The GD-PHF series sleeving is manufactured from PET monofilament that meets the UL94 V1 flammability standard, offering excellent expandability, abrasion resistance, and flame retardancy. The most notable characteristic of this sleeving is its ability to achieve a vertical flame resistance rating of UL94 V0. It is extensively used in areas that require a higher level of flame retardancy, such as automotive wiring harnesses, high-speed rail wiring harnesses, and aviation wiring harnesses.

The GD-PHF series sleeving is manufactured from PET monofilament that meets the UL94 V1 flammability standard, offering excellent expandability, abrasion resistance, and flame retardancy. The most notable characteristic of this sleeving is its ability to achieve a vertical flame resistance rating of UL94 V0. It is extensively used in areas that require a higher level of flame retardancy, such as automotive wiring harnesses, high-speed rail wiring harnesses, and aviation wiring harnesses.

Flame Retardancy: The primary feature of this sleeving is its high flame-retardant capability. It is engineered to resist or inhibit the spread of flames, contributing to improved fire safety in applications where this is a critical concern.

PET Material: PET is known for its flexibility, durability, and resistance to abrasion. The combination of PET material with flame-retardant properties makes this sleeving suitable for applications where both mechanical protection and fire resistance are essential.

Expandable Design: Similar to standard PET expandable braided sleeving, the high flame-retardant version has an expandable design. This allows it to accommodate a range of cable sizes and shapes, making it versatile for various applications.

Temperature Resistance: PET High Flame-Retardant Sleeving is designed to withstand high temperatures, ensuring that it maintains its protective properties even in environments with elevated temperatures.

Electrical Insulation: It may provide electrical insulation, protecting cables and wires from electrical interference and potential short circuits. This is crucial in applications where reliable electrical performance is essential.

Abrasion Resistance: The braided design of the sleeving provides protection against abrasion, impact, and other physical damage, extending the lifespan of cables and wires.

Chemical Resistance: Depending on the specific materials used in the flame-retardant treatment, this sleeving may offer resistance to certain chemicals, enhancing its suitability for use in challenging environments.

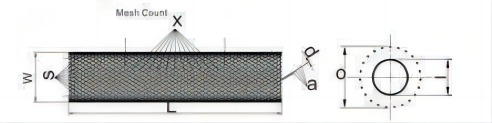

Engineering Picture

PET High Flame-Retardant Sleeving is commonly used in industrial settings where fire safety regulations are stringent. It can be applied to protect cables in machinery, control panels, and other critical electrical systems.

Automotive and Aerospace Industries: Given its flame-retardant properties, this sleeving is suitable for protecting wiring harnesses and cables in vehicles, aircraft, and other transportation applications.

Electronics and Telecommunications: In the electronics and telecommunications industries, where fire safety and cable organization are important, PET High Flame-Retardant Sleeving can be applied to protect and manage cables effectively.

It is extensively used in areas that require a higher level of flame retardancy, such as automotive wiring harnesses, high-speed rail wiring harnesses, and aviation wiring harnesses.

The expandable design allows for easy installation over irregularly shaped or large components. It can accommodate varying diameters, providing a secure and snug fit around cables and wires.

PET High Flame-Retardant Sleeving stands out due to its flame-retardant properties, making it a safer choice in environments where fire hazards are a concern. It combines protection with flexibility and expandability.

This sleeving is often manufactured to meet or exceed safety standards and regulations related to flame resistance. Users should check for specific certifications to ensure compliance with industry requirements.

Yes, the material used in PET High Flame-Retardant Sleeving is often chosen for its durability and resistance to environmental factors, providing reliable protection in challenging conditions.

The braided sleeve is flexible and has a relatively large tolerance in flat width. This information is for reference only.

Special packaging, colors, etc., can be customized according to customer requirements.

Product Part | W: Flat Width | Expansion Range (mm) | Packing (Length/Coil) | ||

Inches | Millimeters | Minimum ID | Maximum ID | ||

PHF-003 | 1/8" | 3 | 1 | 6 | 1000M |

PHF-005 | 1/4" | 6 | 3 | 9 | 500M |

PHF-008 | 5/16" | 8 | 5 | 16 | 350M |

PHF-010 | 3/8" | 10 | 7 | 19 | 350M |

PHF-012 | 1/2" | 12 | 8 | 24 | 300M |

PHF-016 | 5/8" | 16 | 10 | 27 | 250M |

PHF-019 | 3/4" | 19 | 14 | 30 | 200M |

PHF-025 | 1" | 25 | 18 | 35 | 200M |

PHF-032 | 1-1/4" | 32 | 20 | 50 | 150M |

PHF-038 | 1-1/2" | 40 | 30 | 60 | 100M |

PHF-045 | 1-3/4" | 45 | 35 | 75 | 100M |

PHF-050 | 2" | 50 | 40 | 80 | 100M |

PHF-064 | 2-1/2" | 64 | 45 | 105 | 100M |

PHF-076 | 3" | 76 | 64 | 120 | 100M |

PHF-080 | 3-1/4" | 82 | 70 | 135 | 100M |

The braided sleeve is flexible and has a relatively large tolerance in flat width. This information is for reference only.

Special packaging, colors, etc., can be customized according to customer requirements.

Material | Polyester |

Operating Temperature | -50℃ - +150℃ |

Melting Point | 240℃±10℃ |

Flame Resistance Rating | 94-V0 |

Certificate | RoHS,REACH |

Standard Colors | Black, Orange |

Cutting Tool | Hot Knife Cutter |