Product Description

Product DescriptionFabric Heat Shrink Braided Sleeving is a highly durable, flexible, and heat-shrinkable cable management solution designed to protect wires, cables, and pipes in demanding environments. Made from a blend of polyester fiber and polyolefin monofilament, the sleeving undergoes radiation cross-linking to deliver superior strength and performance. When exposed to heat, it shrinks to 50% of its original inner diameter, tightly wrapping cables and providing a neat, professional appearance. This product offers abrasion resistance, thermal insulation, and noise reduction, making it ideal for automotive, electronics, telecommunications, aerospace, and industrial applications.

Premium Material Construction: Woven from polyester fiber and polyolefin monofilament for durability and flexibility.

Heat-Shrink Capability: Shrinks with heat to achieve a secure, form-fitting cable wrap (shrink ratio 2:1).

Excellent Abrasion Resistance: Protects wires and hoses from friction, wear, and surface damage.

High Flexibility: Braided design easily conforms to cables of various shapes, even in tight spaces.

Thermal Performance: Operating temperature range -40℃ to +150℃ with a shrinking temperature of 110℃ – 185℃.

Noise Reduction: Minimizes cable vibration and noise, ideal for automotive and machinery applications.

Certified Quality: Meets RoHS and REACH compliance for safety and environmental standards.

Standard Color: Available in classic black for a professional appearance.

Durable Protection: Extends the lifespan of cables by shielding them from mechanical wear and harsh conditions.

Enhanced Safety: Heat shrink fit reduces risk of loose cables and potential electrical hazards.

Professional Cable Management: Provides a clean and organized look for wiring harnesses and assemblies.

Versatile Usage: Suitable for cables, hoses, and pipes with varying diameters and complex shapes.

Easy Installation: Simple to apply using a heat gun or oven, ensuring efficient on-site assembly.

Automotive Wiring Harnesses: Organizes and protects wiring in vehicles while withstanding vibration and abrasion.

Electronics & Electrical Equipment: Secures internal wiring for household appliances, control boxes, and panels.

Telecommunications: Manages and protects cables in networking racks and data centers.

Aerospace & Aviation: Bundles wires in aircraft systems while ensuring lightweight yet durable protection.

Industrial Machinery: Shields cables in high-friction or high-temperature industrial environments.

Ensure cables are clean and dry before installation.

Use appropriate heat source (heat gun or oven) and maintain proper distance to avoid overheating.

Do not exceed maximum operating temperature to prevent material degradation.

Store below 60℃ in a dry, ventilated area away from direct sunlight.

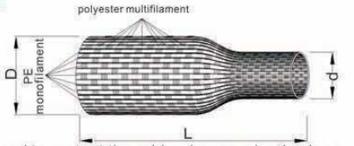

Engineering Picture

Q1: Can Fabric Heat Shrink Braided Sleeving be reused after shrinking?

A1: No, once the sleeving has shrunk, it cannot be reused. A new section must be applied if replacement is needed.

Q2: How do I choose the correct size?

A2: Select a sleeving with an inner diameter approximately 20-30% larger than the cable bundle to allow for easy installation and proper shrink fit.

Q3: Can I cut the sleeving to a custom length?

A3: Yes, the sleeving can be easily cut to the desired length before shrinking.

Q4: Is this product suitable for outdoor use?

A4: Yes, the material is designed to withstand harsh environments and UV exposure, making it suitable for outdoor and automotive use.

Q5: Does it affect the flexibility of cables?

A5: No, its braided design maintains cable flexibility while providing strong protection.

Product Part | (D) Before Shrinking (mm) | (d) After Shrinking (mm) | Packing (Length/Coil) |

KSD-010 | 10 | 5 | 400M |

KSD-012 | 12 | 6 | 350M |

KSD-020 | 20 | 10 | 200M |

KSD-025 | 25 | 12.5 | 150M |

KSD-030 | 30 | 15 | 100M |

KSD-034 | 34 | 17 | 100M |

KSD-040 | 40 | 20 | 100M |

KSD-050 | 50 | 25 | 100M |

KSD-060 | 60 | 30 | 50M |

KSD-070 | 70 | 35 | 50M |

KSD-080 | 80 | 40 | 50M |

Material | Polyolefin+ Polyester |

Operating Temperature | -40℃- +150℃ |

Storage Temperature | ≤60℃ |

Shrinking Temperature | 110℃ - 185℃ |

Shrink Ratio | 2:1 |

Certificate | RoHS,REACH |

Standard Colors | Black |

Shrinking Method | Heat Gun, Oven |