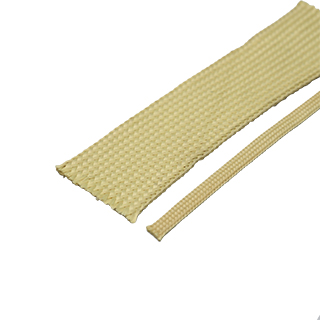

Product Description

Kevlar Braided Sleeving is a premium protective solution designed for cables, hoses, and sensitive components operating in extreme environments. Manufactured from high-strength Kevlar fibers, the GD-KLB series sleeving delivers exceptional abrasion resistance, tensile strength, and thermal stability. Its braided structure ensures flexibility and ease of installation while maintaining lightweight construction. With operating temperature tolerance from -170℃ to +250℃, excellent chemical resistance, and UL94 V0, VW-1 flame retardant rating, Kevlar Braided Sleeving is the preferred choice for aerospace, military, automotive, and high-tech applications where reliability and durability are critical.

Premium Kevlar Fiber Construction:

Made from DuPont Kevlar fibers, known for their extraordinary tensile strength (over 3,600 MPa) and low elongation, ensuring robust protection in high-stress environments.

Superior Abrasion Resistance:

Kevlar’s unique para-aramid structure provides 5x the abrasion resistance of steel on an equal weight basis, shielding cables and hoses from friction damage.

High Temperature Tolerance:

With an operating range of -170℃ to +250℃, Kevlar Braided Sleeving remains stable in extreme hot or cold environments, preventing thermal degradation of protected components.

Outstanding Chemical Stability:

Resistant to most organic solvents, fuels, lubricants, and mild acids/alkalis, making it ideal for use in chemically aggressive environments.

Electrical Insulation:

Kevlar fibers exhibit excellent dielectric strength, adding a layer of electrical protection for wires and sensitive electronics.

Lightweight & Flexible:

Despite its strength, Kevlar Braided Sleeving is lightweight and easy to handle, maintaining flexibility for routing around tight spaces or irregularly shaped components.

Flame Retardant:

Certified to UL94 V0 and VW-1 flame resistance standards, ensuring safety in high-risk applications such as aerospace and defense.

Maximum Protection: Safeguards wires, hoses, and cables from cuts, abrasions, impacts, and thermal damage.

Extended Service Life: Reduces maintenance and replacement costs by significantly increasing component durability.

Professional Finish: Provides a clean, organized, and aesthetically pleasing appearance for wiring harnesses and assemblies.

Versatile Use: Suitable for mechanical, thermal, and electrical protection across multiple industries.

Eco-Friendly & Safe: Complies with RoHS regulations and resists degradation by common chemicals, ensuring long-lasting performance.

Electronics & Electrical Wiring: Protection of cables and wires inside devices and control systems.

Automotive Industry: Ideal for protecting hoses and wiring in engine compartments, exposed to heat, oil, and vibration.

Aerospace & Aviation: Ensures reliability in aircraft wiring harnesses and equipment subject to high mechanical and thermal stress.

Industrial Equipment: Shields cables and hoses in heavy machinery and high-friction environments.

Military & Defense: Used in mission-critical applications where strength, flame resistance, and durability are paramount.

Medical Devices: Protects wiring in diagnostic equipment and hospital tools, where reliability is essential.

Sports Equipment: Applied in racing bikes, skateboards, and performance gear for lightweight reinforcement.

Use Proper Cutting Tools: Kevlar fibers are tough—use sharp scissors to achieve a clean cut.

Seal the Ends: To prevent fraying, apply heat-shrink tubing or resin to the cut ends after installation.

Avoid Overstretching: Although Kevlar is strong, excessive stretching during installation may reduce its performance.

Store Properly: Keep in a dry, ventilated area, away from direct sunlight and high humidity to maintain fiber integrity.

Q1: How strong is Kevlar Braided Sleeving?

A1: Kevlar braided sleeving offers exceptional tensile strength and cut resistance, outperforming most other sleeving materials under extreme stress.

Q2: Can it withstand high temperatures?

A2: Yes, Kevlar sleeving can operate continuously from -170℃ to +250℃ without losing structural integrity.

Q3: How is it installed?

A3: Simply slide the sleeving over the cable, hose, or wire bundle. Secure ends with heat-shrink tubing or mechanical fasteners for a clean finish.

Q4: Can Kevlar Braided Sleeving be cut to size?

A4: Yes, it can be easily cut with sharp scissors or a utility knife. Sealing the ends is recommended to avoid fraying.

Q5: Is Kevlar resistant to chemicals?

A5: Kevlar demonstrates excellent resistance to most common solvents, fuels, and chemicals, making it suitable for harsh environments.

The braided sleeve is flexible and has a relatively large tolerance in flat width. This information is for reference only.

Special packaging, colors, etc., can be customized according to customer requirements.

Product Part | W: Flat Width | Expansion Range (mm) | Packing (Length/Coil) | |

Millimeters | Minimum ID | Maximum ID | ||

KLB-003 | 3 | 1 | 4 | 500M |

KLB-006 | 6 | 5 | 8 | 500M |

KLB-008 | 8 | 6 | 10 | 350M |

KLB-010 | 10 | 7 | 13 | 350M |

KLB-012 | 12 | 8 | 16 | 300M |

KLB-015 | 15 | 10 | 20 | 250M |

KLB-020 | 20 | 14 | 26 | 200M |

KLB-025 | 25 | 18 | 33 | 200M |

KLB-030 | 30 | 20 | 39 | 150M |

KLB-040 | 40 | 30 | 52 | 150M |

KLB-050 | 50 | 40 | 65 | 150M |

The braided sleeve is flexible and has a relatively large tolerance in flat width. This information is for reference only.

Special packaging, colors, etc., can be customized according to customer requirements.

Material | Kevlar fiber |

Operating Temperature | -170℃ - +250℃ |

Melting Point | -- |

Flame Resistance Rating | UL94 V0, VW-1 |

Certificate | RoHS |

Standard Colors | Yellow |

Cutting Tool | Scissors |

Other Properties | Resistant to organic solvents |