PTFE Spiral Wrap/Cut Tubing offers exceptional chemical resistance, high temperature tolerance, and flexibility. Ideal for demanding applications, it's non-stick, electrically insulating, and can be customized to various lengths and diameters.

Material Characteristics

Material CharacteristicsMaterial: PTFE (Polytetrafluoroethylene), also known as Teflon.

Chemical Properties: Inorganic chemical stability, impervious to acids, bases, solvents, and oxidizers.

Temperature Range: Maintains excellent performance in extreme temperatures ranging from -200°C to +260°C.

Low Friction Coefficient: Exhibits an extremely low friction coefficient, making it an excellent lubricating material.

Insulation Properties: Offers outstanding insulation properties suitable for electrical applications.

Non-Adhesive Nature: Surface is highly non-adhesive, resistant to solid or liquid substances adhering to it.

Biocompatibility: Suitable for medical devices.

Corrosion Resistance: Demonstrates exceptional resistance to corrosion, ideal for the conveyance of corrosive liquids or gases.

High-Temperature Resistance: Maintains stability under high-temperature conditions, suitable for high-temperature applications.

Mechanical Strength: Exhibits good mechanical properties, including tensile and impact strength.

Dimensional Stability: Maintains dimensional stability under temperature variations, minimizing expansion or contraction.

Age Resistance: Offers a prolonged service life, resistant to aging or deterioration.

Outstanding Corrosion Resistance: Suitable for various corrosive environments due to its chemical stability.

Outstanding Corrosion Resistance: Suitable for various corrosive environments due to its chemical stability.

Versatility: Applicable to the conveyance of liquids and gases and utilized across a wide range of industries.

Low Friction Coefficient: Reduces energy loss and wear, enhancing efficiency.

Non-Adhesive Nature: Reduces material adhesion, making it easy to clean and maintain.

Insulation Properties: Appropriate for electrical insulation and the manufacturing of insulating components.

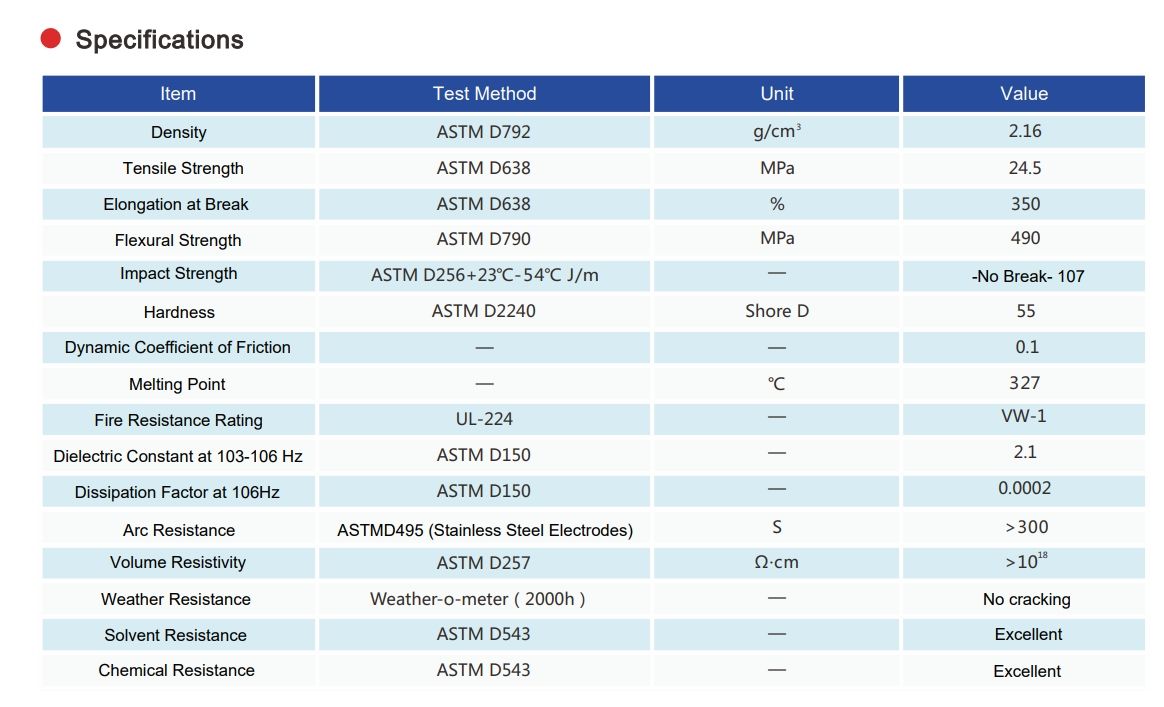

Our PTFE Tube complies with RoHS, REACH, and FDA requirements.

Our PTFE Tube meets the VW-1 flame resistance rating.

Product Applications

Chemical Industry: Used for conveying acids, bases, solvents, and other corrosive media.

Food and Pharmaceutical Industry: Applied in food processing equipment and medical devices.

Electrical Field: Utilized as wire insulation material and electrical component components.

Liquid Conveyance: Employed for conveying chemicals, petroleum products, and corrosive liquids.

Automotive Industry: Widely used in automotive braking systems and lubrication systems.

The manufacturing process of PTFE Spiral Wrap/Cut Tubing involves extruding PTFE resin into a tube shape. The spiral wrap design is achieved by winding the tubing in a helical manner, while cut tubing is precisely measured and sliced. Understanding the manufacturing process is crucial for ensuring the tubing's quality and performance.

PTFE Spiral Wrap/Cut Tubing exhibits several key characteristics, including high chemical resistance, excellent thermal stability, low friction coefficient, and electrical insulation properties. These features make it suitable for demanding applications where resistance to harsh chemicals and extreme temperatures is essential.

PTFE is inherently resistant to a wide range of chemicals, making PTFE Spiral Wrap/Cut Tubing an ideal choice for applications where exposure to corrosive substances is a concern. Exploring the molecular structure and properties of PTFE provides insights into its remarkable chemical resistance.

Thermal stability is a critical factor in applications exposed to extreme temperatures. PTFE Spiral Wrap/Cut Tubing maintains its structural integrity and performance in high-temperature environments. Exploring the molecular and thermal properties of PTFE provides insights into its stability under varying temperature conditions.

Proper installation is crucial for maximizing the effectiveness of PTFE Spiral Wrap/Cut Tubing. This includes considerations such as proper sizing, securing the tubing in place, and understanding the environmental conditions. Exploring installation best practices ensures the tubing performs optimally in its intended application.

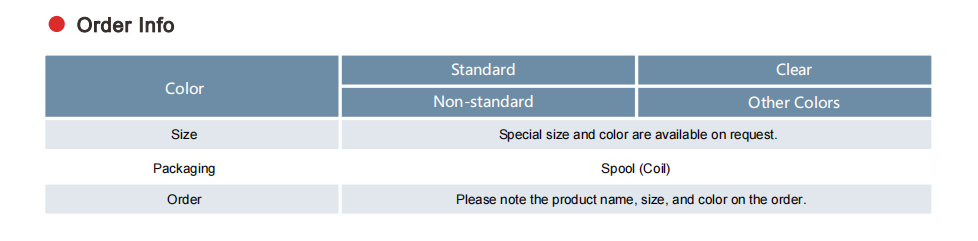

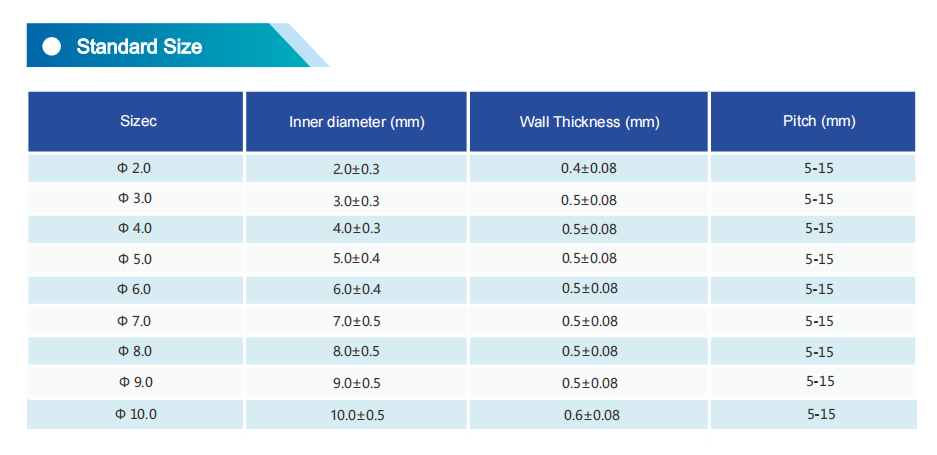

Custom sizes and specifications beyond the list are available on request.

Custom sizes and specifications beyond the list are available on request.

Top