Product Description

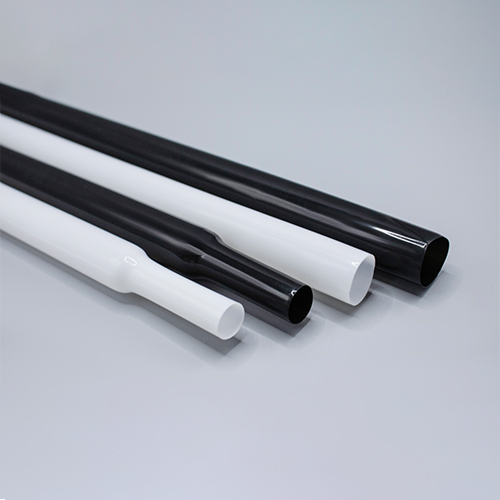

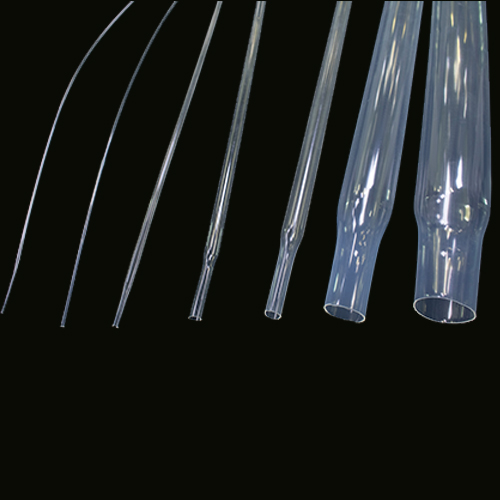

FEP Heat Shrink Tubing, made from high-purity fluorinated ethylene propylene (FEP), provides exceptional electrical insulation, high chemical resistance, and superior thermal stability. This advanced fep tubing shrinks tightly around wires, cables, connectors, and other components when heat is applied, ensuring secure protection and enhanced performance. With its excellent optical clarity, UV resistance, and non-stick surface, fep heat shrink tubing is widely used in industries requiring high reliability and clean insulation solutions.

Product Features

Outstanding Thermal Resistance

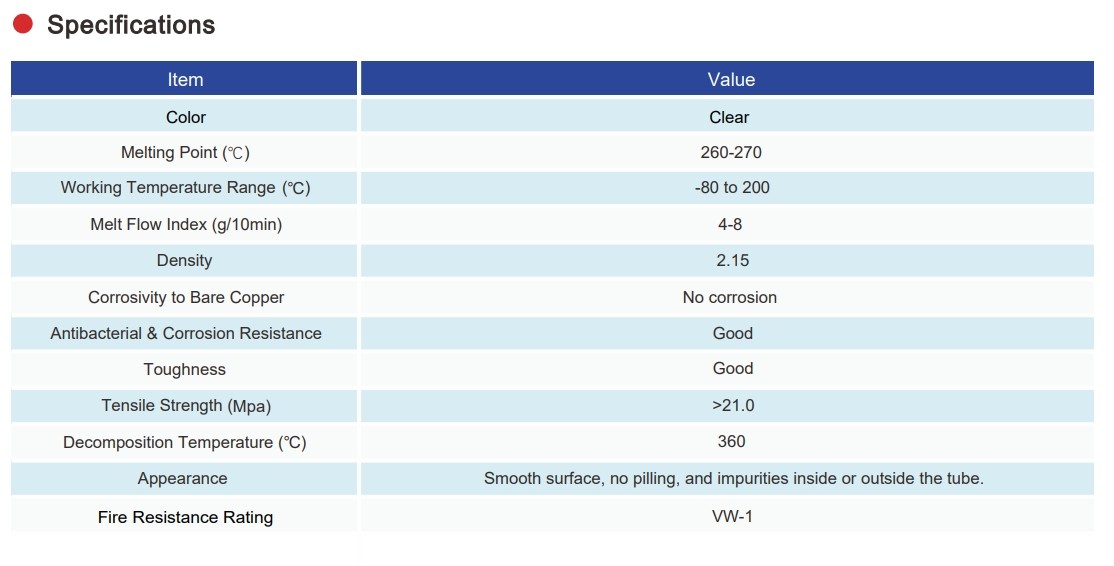

Because FEP has a melting point of around 260°C (500°F) and maintains stability over a wide temperature range, it provides excellent heat resistance and ensures long-term reliable insulation in high-temperature environments.

Superior Chemical Resistance

Because the molecular structure of FEP is highly stable and non-reactive, it resists almost all industrial chemicals—including strong acids, bases, and solvents—so the tubing maintains durability and performance even in corrosive conditions.

Excellent Electrical Insulation

Because FEP exhibits a very low dielectric constant and power factor, it significantly reduces power loss, so fep heat shrink tubing is an ideal choice for high-voltage insulation in sensitive electronic systems.

High Transparency

Because FEP material has excellent optical clarity, the tubing allows easy visual inspection of wires and connectors, helping engineers quickly identify potential issues during installation and maintenance.

UV and Weather Resistance

Because FEP resists UV rays and extreme weather, it can be used both indoors and outdoors, ensuring long-term stability without degradation from sunlight or harsh environments.

Non-Stick Surface

Because the FEP surface is naturally non-stick, dust, oils, and other contaminants are less likely to adhere, making it easier to clean and maintain cables in demanding environments.

Product Advantages

Reliable Protection: Prevents cables and connectors from mechanical wear, corrosion, and environmental damage.

Enhanced Safety: Provides flame resistance (VW-1 rating) and helps minimize risks of electrical failure.

Low Maintenance Cost: Long service life reduces replacement frequency and downtime.

Space-Efficient Design: Shrinks uniformly around components, saving installation space compared to bulky protective covers.

Compliance: Meets RoHS, REACH, and FDA requirements, ensuring global applicability.

Precautions / Notes

Ensure proper heating temperature (generally 175–200°C) for uniform shrinking.

Avoid excessive heating to prevent damage or deformation.

Store in a cool, dry place away from direct sunlight and corrosive environments.

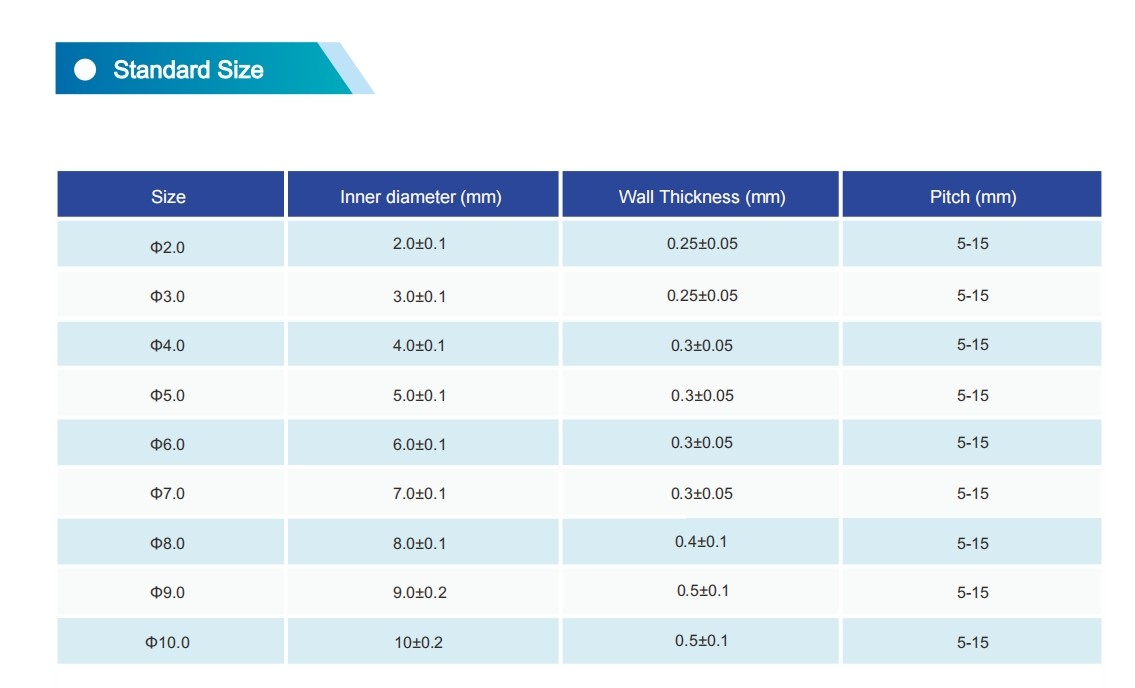

Choose the correct size: recommended shrink ratio is typically 1.6:1 or 2:1 for fep heat shrink tubing.

Application Areas

Medical Devices: Used in catheter delivery systems and surgical equipment for insulation and protection.

Automotive Industry: Ideal for EV battery insulation and high-voltage cable protection.

Aerospace: Low outgassing properties make FEP tubing suitable for vacuum and space applications.

Semiconductor & Electronics: Protects sensor cables, wiring, and components in high-temperature and corrosive environments.

Food & Pharmaceutical:FDA compliant, ensuring safe use in production lines and laboratory equipment.

Industrial & Telecommunications:Provides EMI shielding and reliable cable insulation in complex industrial systems.

Q1: What is the main difference between FEP tubing and FEP heat shrink tubing?

A1: Standard fep tubing is used as-is for insulation and fluid transfer, while fep heat shrink tubing shrinks with heat to form a tight protective seal around components.

Q2: What shrink ratios are available?

A2: Common shrink ratios include 1.6:1 and 2:1, ensuring proper fit for various wire and connector sizes.

Q3: Can FEP heat shrink tubing withstand outdoor use?

A3: Yes. It has excellent UV and weather resistance, making it suitable for harsh outdoor applications.

Q4: Is FEP heat shrink tubing FDA compliant?

A4: Yes. Our fep tubing meets FDA, RoHS, and REACH standards, making it suitable for medical, food, and pharmaceutical industries.

Q5: Does it provide flame resistance?

A5: Yes. It meets VW-1 flame resistance rating, ensuring enhanced safety in critical environments.

Our FEP SPIRAL WRAP/CUT TUBING complies with RoHS, REACH, and FDA requirements.

It also meets the VW-1 flame resistance rating.

Custom sizes and specifications beyond the list are available on request.

Custom sizes and specifications beyond the list are available on request.