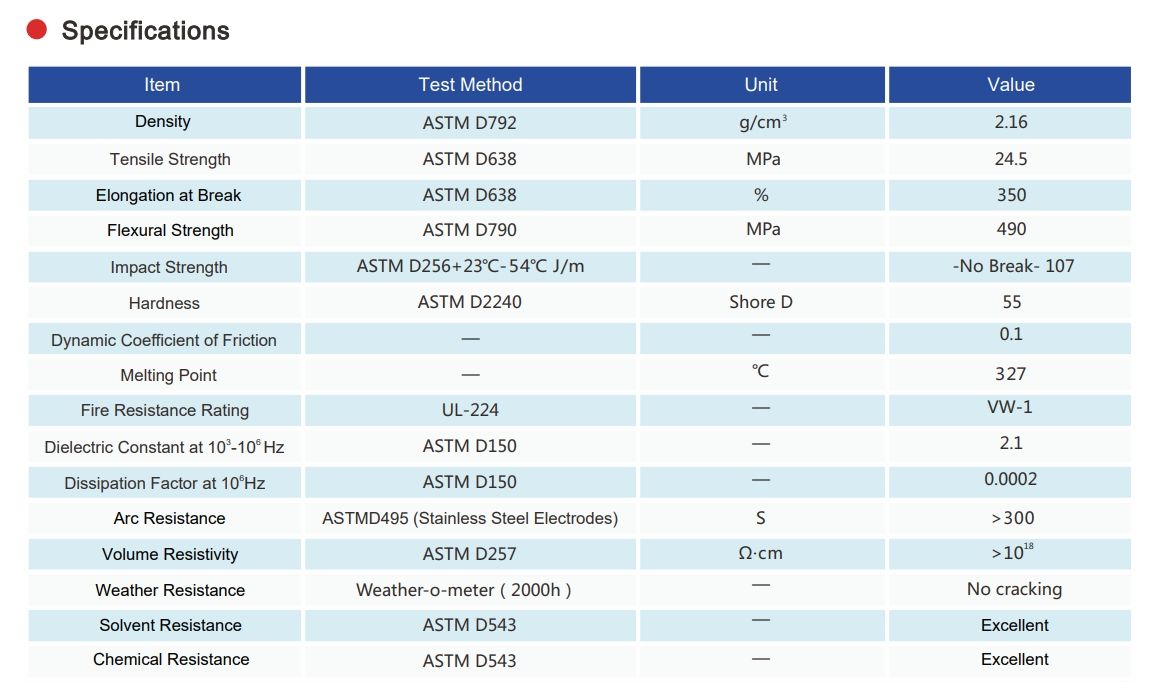

PTFE TUBING

PTFE tubing, short for Polytetrafluoroethylene tubing, is a high-performance fluoropolymer tubing known for its outstanding chemical resistance, thermal stability, non-stick surface, and electrical insulation. Compliant with RoHS, REACH, and FDA regulations, it is a preferred solution across chemical processing, medical devices, food handling, and electronic insulation applications. With a wide operating temperature range and flame resistance (VW-1), PTFE tubing delivers reliable performance even in extreme environments.

PTFE tubing, short for Polytetrafluoroethylene tubing, is a high-performance fluoropolymer tubing known for its outstanding chemical resistance, thermal stability, non-stick surface, and electrical insulation. Compliant with RoHS, REACH, and FDA regulations, it is a preferred solution across chemical processing, medical devices, food handling, and electronic insulation applications. With a wide operating temperature range and flame resistance (VW-1), PTFE tubing delivers reliable performance even in extreme environments.

Chemical Stability: PTFE is a highly stable material, exhibiting excellent resistance to a wide array of chemicals, including acids, alkalis, solvents, and more. This makes it an ideal choice for transporting corrosive chemicals in the chemical industry.

Thermal Stability: PTFE tubes can operate within a broad temperature range, from extremely low temperatures to high temperatures (-200°C to +260°C). It maintains stability at high temperatures without undergoing decomposition or deformation, rendering it suitable for high-temperature applications.

Non-Stick Property: PTFE features exceptional non-stick properties with a surface that is incredibly smooth, preventing almost any substances from adhering to its surface. This property makes it particularly useful in the food processing and liquid conveying industries.

Electrical Insulation: PTFE tubes exhibit outstanding electrical insulation properties, making them suitable for electrical engineering and electronic applications, reducing electrical risks.

Low Friction Coefficient: PTFE displays an extremely low friction coefficient, making it an ideal choice for applications such as bearings, seals, and lubrication.

Corrosion Resistance: PTFE tubes resist the corrosive effects of various chemicals, making them highly durable in corrosive environments. This quality makes them suitable for use in the chemical industry for pipelines, valves, and equipment.

High-Temperature Stability: PTFE tubes can maintain their performance in high-temperature environments without undergoing decomposition or aging. This suitability for high-temperature applications extends to heat exchangers and chemical processing equipment.

Electrical Insulation: PTFE tubes exhibit superior electrical insulation properties, helping to prevent electrical shocks and electrical faults, making them a dependable choice for electrical engineering and electronic applications.

Non-Stick Property: The non-stick surface of PTFE tubes hardly attracts impurities, reducing maintenance costs and rendering them suitable for use in food processing and manufacturing.

Biocompatibility: PTFE is non-toxic to living organisms, making it suitable for use in medical devices and biomedical applications, including catheters, tubing, and valves.

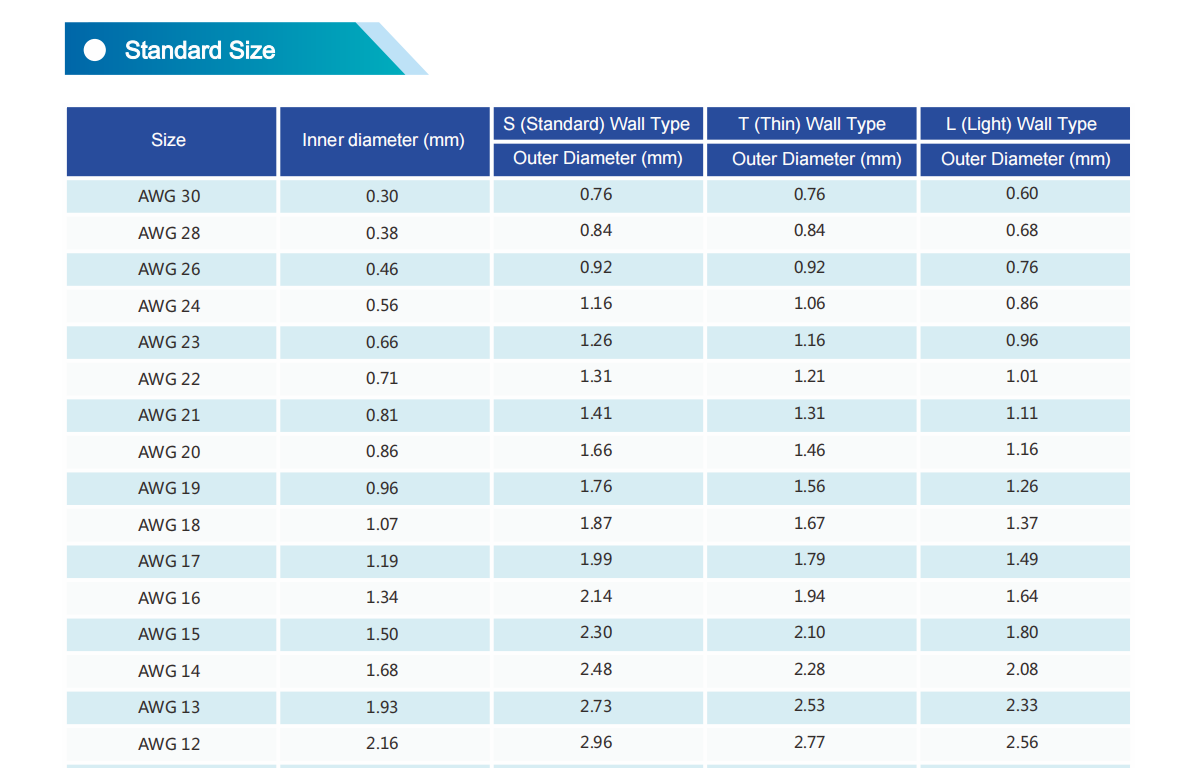

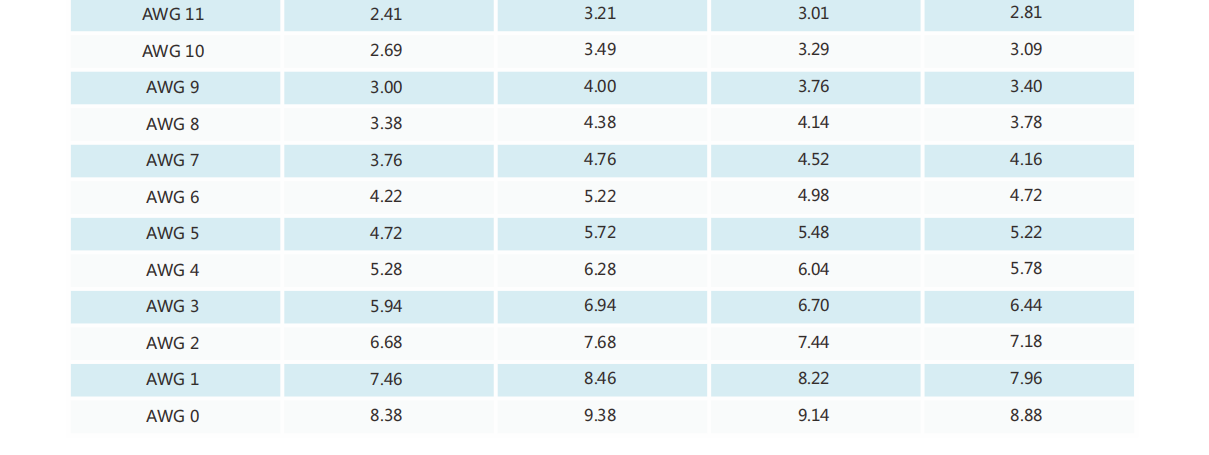

Available Sizes and Customization Options

Inner Diameter Range: 0.2 mm – 25 mm (customizable)

Wall Thickness: 0.1 mm – 2 mm

Lengths: Cut-to-length or continuous roll

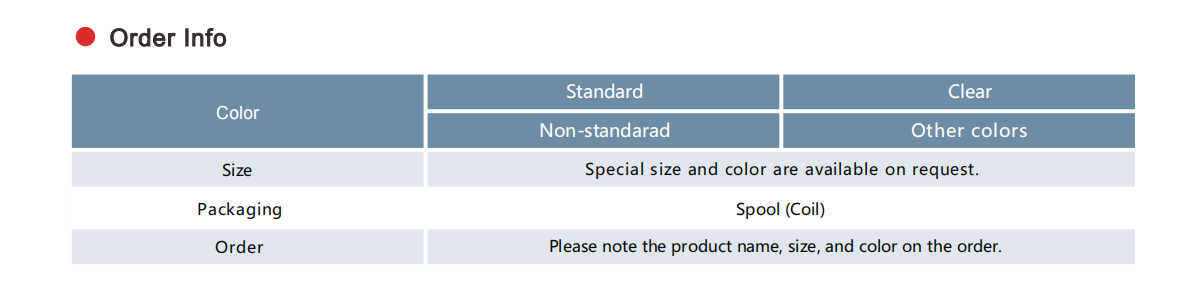

Color: Transparent, White, Black, or Colored PTFE

Options: Smooth bore, convoluted, heat shrink, and multi-lumen tubing

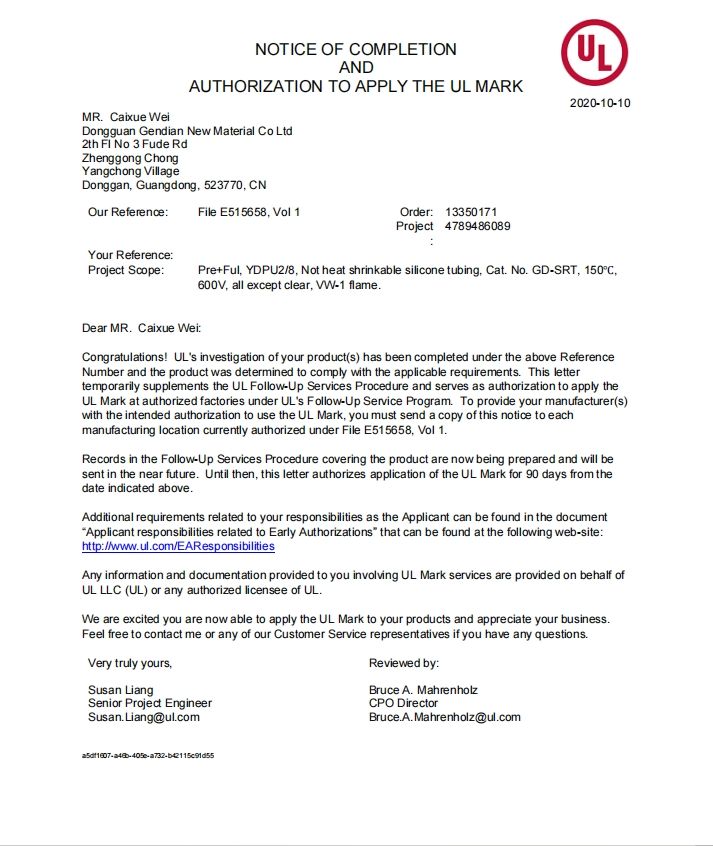

Certifications: RoHS, REACH, FDA, UL VW-1

PTFE tubes find widespread applications across various fields, including but not limited to:

PTFE tubes find widespread applications across various fields, including but not limited to:

Chemical Industry: Used for transporting corrosive chemicals in pipelines, valves, and equipment.

Food Processing: Employed for food transport, pipelines, and equipment due to its non-stick and hygienic properties.

Medical Devices: Used in medical device components such as catheters, tubing, and valves, thanks to its biocompatibility.

Electrical and Electronic Engineering: Utilized for wire insulation, electrical components, and cables, given its excellent electrical insulation properties.

Lubrication Applications: Used as a solid lubricant or lubricating oil additive to reduce friction and wear.

Pharmaceutical manufacturing

Semiconductor processing

Laboratory research facilities

Automotive fluid transfer systems

3D printing and extrusion systems

Aerospace fluid lines

Battery and fuel cell development

PTFE tubing, or polytetrafluoroethylene tubing, is a unique material known for its exceptional properties. This section explores its composition, characteristics, and what distinguishes it from other types of industrial tubing.

Delve into the chemical resistance of PTFE tubing, understanding how this material stands up to corrosive substances, making it a preferred choice in industries where chemical resistance is paramount.

Explore the specific attributes of PTFE tubing that make it a preferred option in medical and laboratory settings. This may include its biocompatibility, clarity, and resistance to contamination.

Explore the diverse sizes and variations of PTFE tubing available in the market. Understand how these options cater to specific application requirements, ensuring a precise fit for various industries.

Custom sizes and specifications beyond the list are available on request.

Custom sizes and specifications beyond the list are available on request.