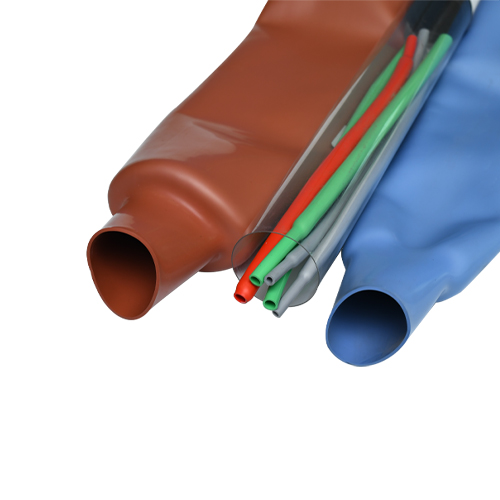

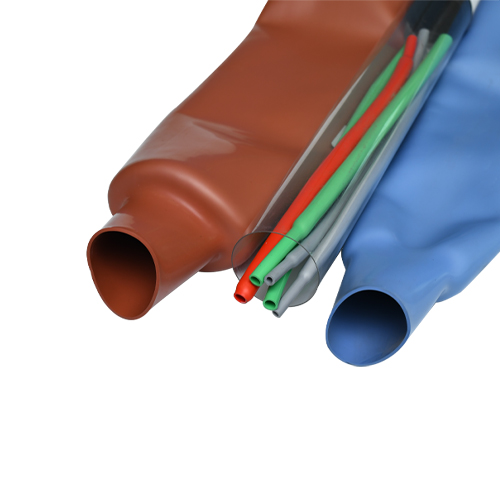

Heat-Shrinkable Silicone Rubber Tubing is made of high quality silicone rubber material with excellent resistance to high temperature, arc and corona. Its unique heat-shrinkable function can closely fit the protected object after heating, forming a solid insulating layer. The product is soft and easy to install, suitable for insulation protection of electrical appliances, lamps, electronic instruments and other equipment. Meanwhile, it is non-toxic and odorless, in line with environmental protection requirements, widely used in electric power, chemical industry, medical and other fields to ensure the safe and stable operation of equipment.

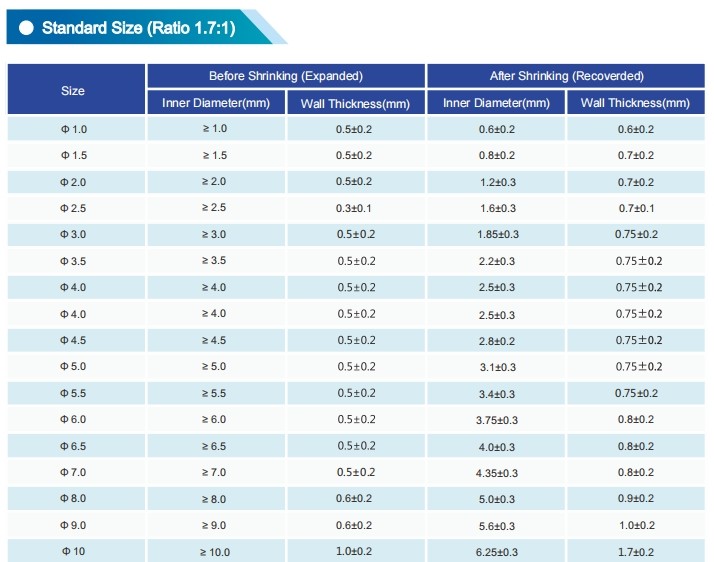

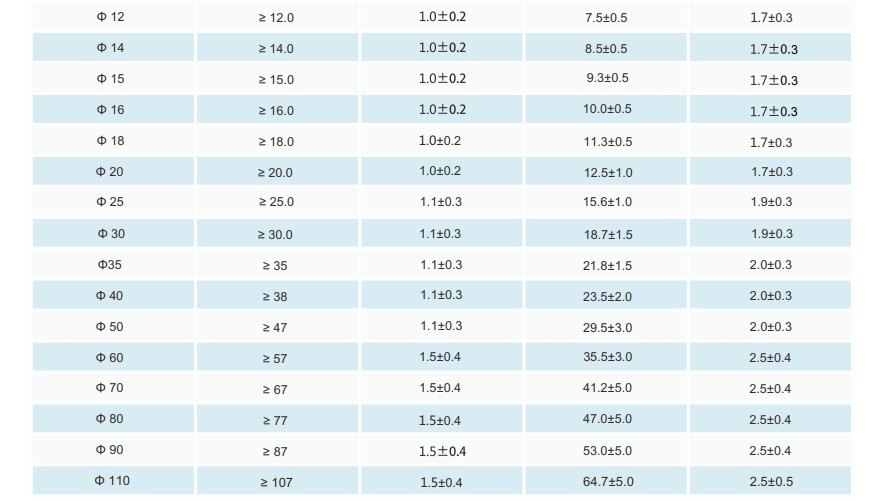

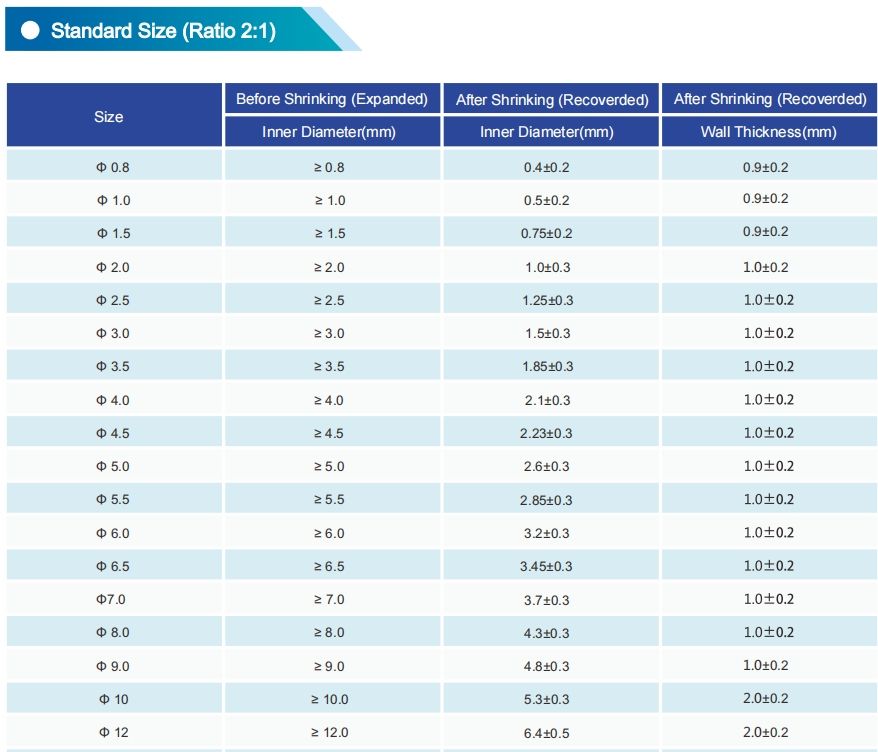

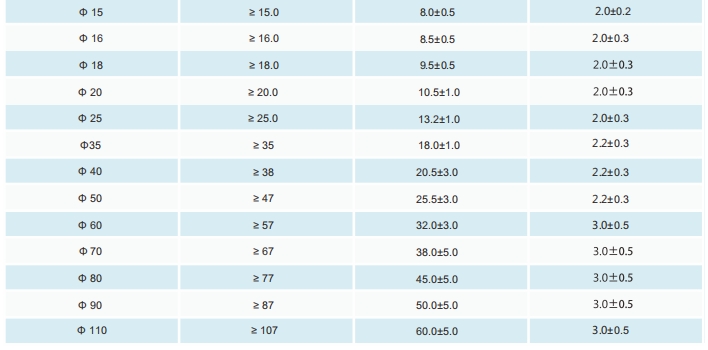

Shrink Ratio: (1.7:1)&(2:1)

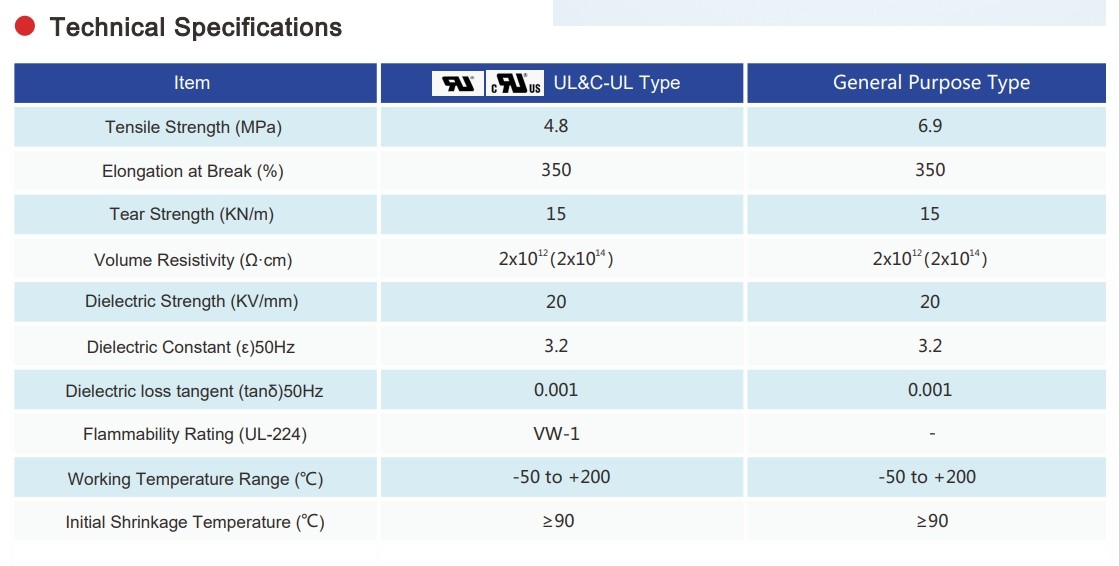

High-Temperature Resistance: Silicone heat shrink tubing is capable of withstanding extreme temperatures, ranging from as low as -50°C to as high as +200°C, rendering it highly reliable in high-temperature environments.

Chemical Resistance: Silicone heat shrink tubing exhibits excellent resistance to acids, alkalis, solvents, and other chemical substances, making it a suitable choice for harsh chemical environments.

Excellent Electrical Insulation: Silicone heat shrink tubing offers outstanding electrical insulation, making it ideal for wire insulation and electrical equipment maintenance. It helps protect wires from electrical shocks and other electrical faults.

Waterproof Performance: The superior waterproof properties of silicone heat shrink tubing effectively prevent moisture and humidity from compromising wires and connectors.

Features

FeaturesHigh Elasticity: Silicone heat shrink tubing possesses remarkable elasticity, enabling it to adapt to objects of various shapes, whether they are circular or irregular. This feature makes it easy to install and adaptable to diverse application requirements.

Ease of Installation: Silicone heat shrink tubing rapidly shrinks to encapsulate and seal objects through a simple heating process, typically utilizing a heat gun or other heat sources.

Durability: Silicone heat shrink tubing typically has a long service life and is resistant to damage or aging. It can maintain its performance and protective qualities over many years.

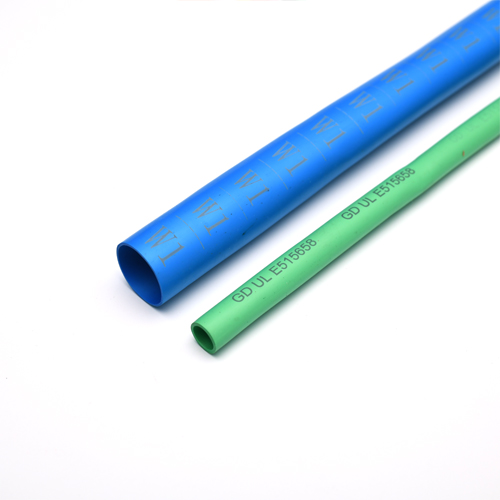

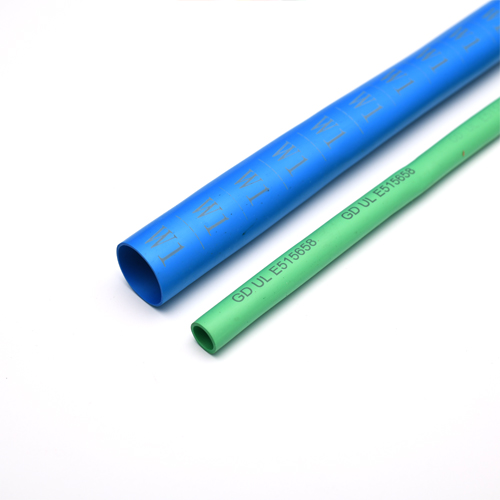

Customizable Sizes: Silicone heat shrink tubing offers a range of size and color options to meet specific application needs, providing flexibility to accommodate various projects.

GD-SHT complies with RoHS, REACH, and FDA requirements.

GD-SHT obtained UL/C-UL flame resistance certifications, meeting the VW-1 flame resistance rating.

Application

ApplicationSilicone heat shrink tubing finds extensive applications across various industries, including but not limited to:

Electronics and Electrical Engineering: Used for wire insulation, connector protection, electronic component encapsulation, and cable management.

Automotive Industry: Applied for insulating and sealing automotive cables and connector components to protect them from moisture and chemical substances.

Industrial Sector: Utilized for pipeline maintenance, protection, cable bundle management, and sealing applications.

Medical Devices: Employed in medical equipment for insulation and sealing to ensure the reliability and safety of the devices.

GD-SHT is a self-developed product of our company and holds a national invention patent in China.

FAQ:

Silicone heat shrink tubing is made of materials such as silicone and polyolefin, and has good elasticity and plasticity. When heated by a heat source, the internal materials will flow and uniformly adhere to the protected object. As the temperature increases, the silicone heat shrink tube will shrink and tightly wrap around the protected object, playing a protective and sealing role.

When using silicone heat shrink tubing, first place the protected object inside the tubing, and then use a heat source (such as a hot air gun or oven) to heat the tubing, causing it to shrink and tightly wrap around the protected object.

Yes, silicone heat shrink tubing has good high-temperature resistance and can be used in high-temperature environments.

Compared with other types of pipes, silicone heat shrinkable pipes have better heat resistance, electrical insulation, chemical stability, aging resistance and other advantages, and are more convenient to operate.

When using silicone heat shrink tubing, safety precautions should be taken, such as avoiding use in flammable and explosive environments and preventing burns.

The time required for complete shrinkage of silicone heat shrink tubing depends on factors such as its specifications, material, and heat source. Generally, it takes several seconds to minutes to fully shrink.

Yes, silicone heat shrink tubing has good insulation and protective properties, and can be used for insulation protection of wires and cables, as well as sealing and protecting various components such as pipes, joints, valves, etc.

Top