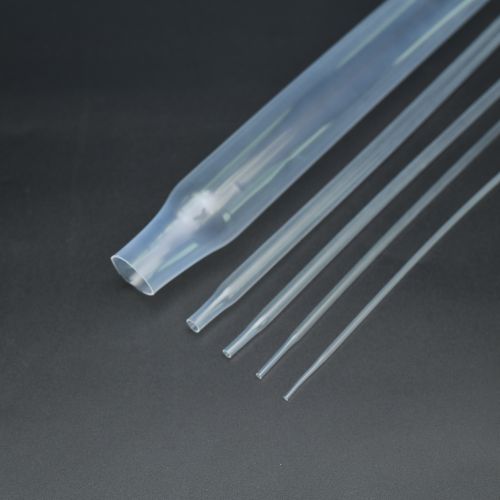

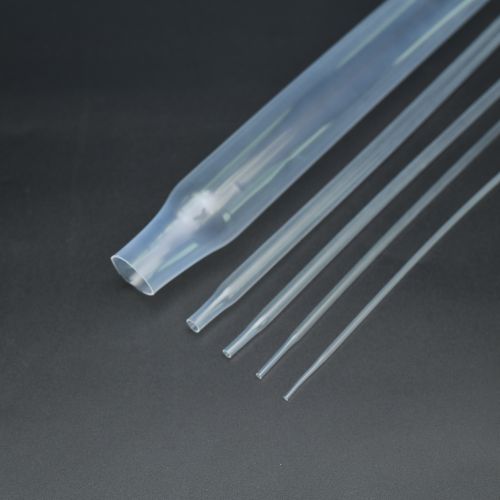

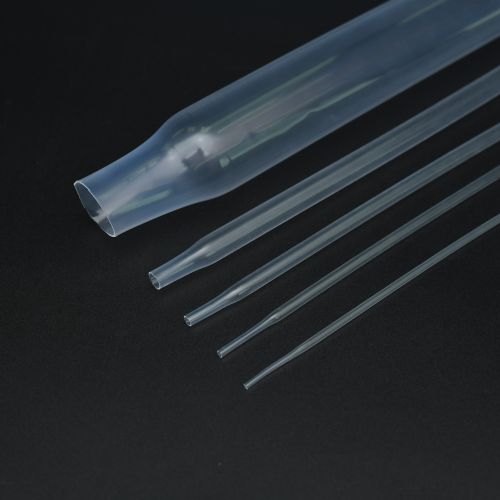

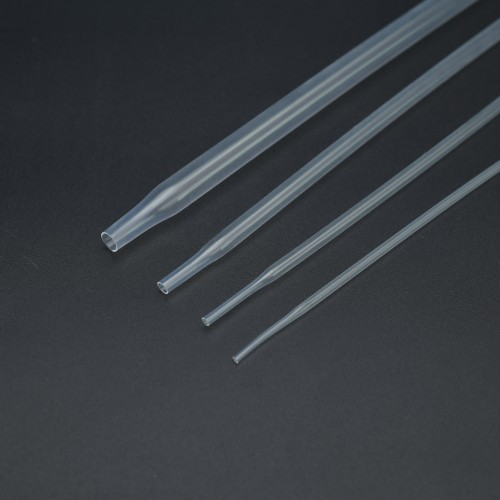

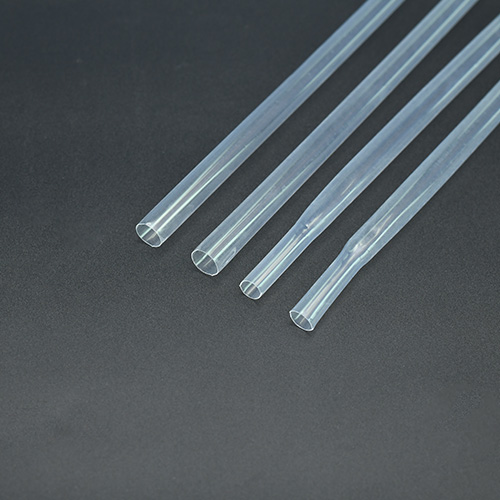

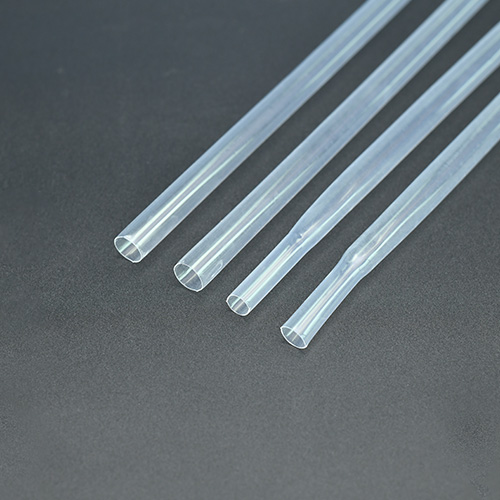

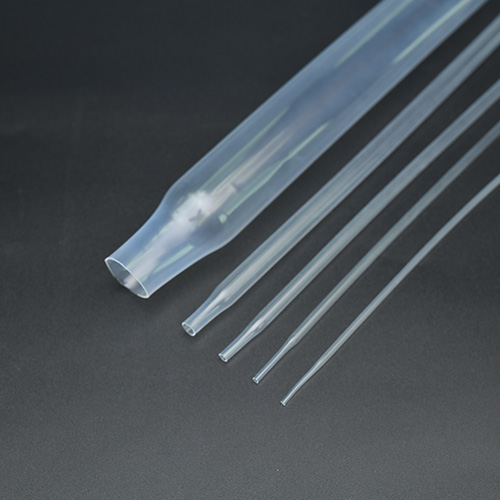

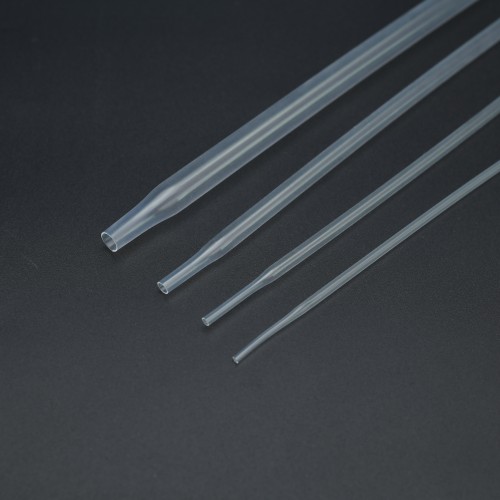

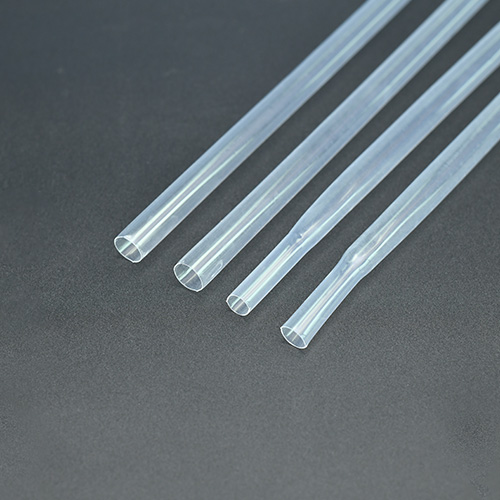

FEP/PFA/ETFE Heat Shrink Tubing is a high-performance heat shrink tubing with excellent resistance to high and low temperatures, chemical corrosion, high insulation and non-adhesion. It is widely used in the insulating sheaths of electrical components, instruments, wires and cables, as well as the surface film wrapping of rollers in the paper and textile industries. In addition, this heat shrinkable tube is also suitable for various places with harsh working conditions, providing explosion-proof, anti-corrosion and anti-adhesive functions. The material is lightweight and transparent for easy viewing and installation, and has good shrinkage to ensure a tight fit and provide reliable insulation protection.

Temperature Range: Functional between -200°C and 200°C, with short-term thermal resistance up to 260°C.

Transparency: High clarity allows for visual inspection, ideal for applications where monitoring of internal fluid or cable condition is necessary.

UV Resistance: Demonstrates negligible aging from UV exposure, suitable for outdoor applications.

Dimensional Stability:Retains dimensional integrity under extreme temperatures, without expansion or shrinkage.

Low Friction Coefficient: The smooth surface resists adhesion, facilitating easy cleaning and maintenance.

Shrink Ratio: Generally ranging from 1.3:1 to 1.6:1,and 2:1 accommodating various outer diameters of objects.

Product Advantages

Product AdvantagesExcellent Electrical Insulation: An ideal choice for high-frequency applications or situations demanding electrical insulation.

Chemical Resistance: Virtually unaffected by all chemicals, including aggressive acids, bases, and most solvents.

Non-Toxic: Compliant with food-grade requirements, suitable for direct food contact.

Medical Equipment: Provides a non-toxic protective layer, applicable for endoscopic and other medical devices.

Laboratory and Chemical Processing: Protection for tubing and cables, especially in corrosive chemical environments.

Food Processing: Direct contact with food items, shielding pipes and cables from contamination.

Material Introduction and Chemical Composition

FEP/PFA/ETFE Heat Shrink Tubing is made from tetrafluoroethylene and perfluorovinyl ethers. It combines the benefits of PTFE with the processing ease of FEP. The perfluoroalkoxy side chains in its molecular structure offer high thermal stability and excellent resistance to chemical corrosion.

Temperature Range: Long-term serviceability from -200°C to +260°C, suited for extreme environments.

Purity: Its very low leach-out rates make it ideal for high-purity applications.

Stress Crack Resistance: Exhibits superior resistance to environmental stress cracking compared to FEP.

Non-stick Surface: Highly suitable for applications that demand clean surfaces, such as coatings and encapsulating components.

High Transparency: Allows monitoring of internal flowing substances, ensuring operational precision.

Performance at Extreme Temperatures: Capable of enduring continuous high temperatures, appropriate for environments that require prolonged exposure to heat.

High Purity Processing: Extremely suitable for semiconductor manufacturing and biopharmaceutical processes that have stringent material purity demands.

Thermal Stability: Apt for heating processes and thermal cycling applications, like heat exchangers and sample containers.

Semiconductor Manufacturing: Protective encapsulation for sensitive components under stringent cleanroom conditions.

Biotechnology and Pharmaceutical: Employed in aseptic processes to maintain high-purity environments.

Chemical Processing: Acts as a protective layer for chemical equipment to prevent corrosion and contamination.

Material Introduction and Chemical Composition

ETFE (Ethylene Tetrafluoroethylene) is a copolymer of ethylene and tetrafluoroethylene, known for its superior mechanical strength and toughness over other fluoropolymers. Its material composition enables ETFE to withstand mechanical stress across a broader spectrum of applications.

High Mechanical Performance: Exhibits higher tensile strength and impact resistance than many other thermoplastic materials.

Radiation Resistance: Displays better resistance to high doses of radiation, suitable for environments with significant radiation exposure.

Good Chemical Resistance: While not as resistant as PFA and FEP, ETFE still offers excellent chemical resistance.

Environmental Adaptability: Exhibits better resilience against environmental factors such as temperature fluctuations and humidity in outdoor applications.

Abrasion Resistance: Provides additional protection in environments with high friction, like dynamic systems or frequently moving parts.

Strength and Toughness: Capable of enduring heavy loads and impacts, suitable for protecting equipment that is susceptible to mechanical damage.

Strength and Toughness: Capable of enduring heavy loads and impacts, suitable for protecting equipment that is susceptible to mechanical damage.

Versatility: Applicable for creating films, sheets, and heat shrink tubing, with widespread use across different markets and products.

Processability: Can be molded through various processes such as blow molding and injection molding, offering high design flexibility.

Construction Industry: Appropriate for creating highly durable architectural membrane materials, such as stadium roofing.

Aerospace: Used to protect cables and sensors on the exteriors of spacecraft.

Automotive Industry: Due to its wear-resistant properties, it is suitable for protecting wiring harnesses inside vehicles.

Advantages of FEP Heat Shrink Tubing:

Low-Temperature Flexibility: FEP retains flexibility at very low temperatures, suitable for applications operating in cold environments.

Transparency: The high transparency of FEP allows for easy internal inspection, crucial for applications requiring visibility of internal components.

Shrink Ratio: A relatively higher shrink ratio means FEP can adapt to a wider range of component sizes.

Advantages of PFA Heat Shrink Tubing:

Extreme Temperature Performance: PFA outperforms FEP in high-temperature applications, suitable for long-term high-temperature endurance.

Chemical Stability: PFA offers superior chemical stability over FEP, particularly fitting for high-purity chemical processing fields.

Stress Crack Resistance: PFA has stronger resistance to environmental stress cracking, crucial for preventing material fatigue over long-term use.

Advantages of ETFE Heat Shrink Tubing:

Mechanical Performance: With superior mechanical properties over FEP and PFA, ETFE is ideal for applications subjected to greater mechanical stress.

Radiation Resistance: ETFE performs better in radioactive environments, suitable for use in nuclear energy and aerospace fields.

Abrasion Resistance: ETFE's abrasion resistance makes it more durable in environments where frequent movement or high friction is present.

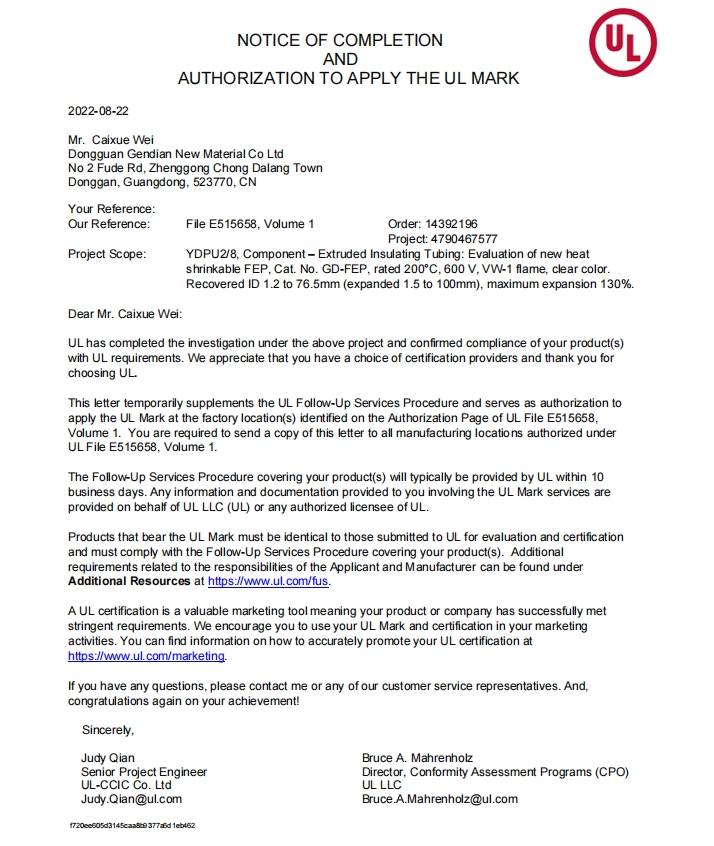

Our GD-FEP, PFA, and ETFE complies with RoHS, REACH, and FDA requirements.

Our GD-FEP has passed UL/C-UL Flame resistance test, meeting the VW-1 flame resistance rating.

Top