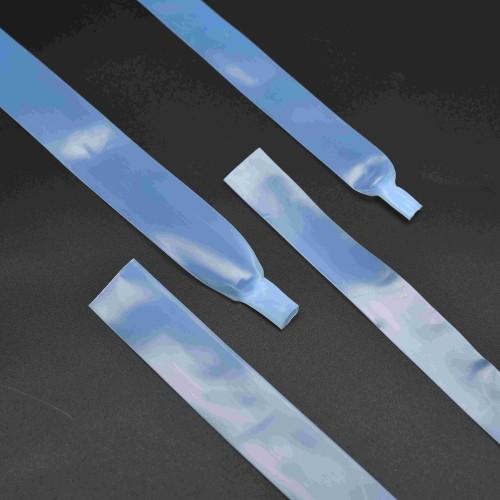

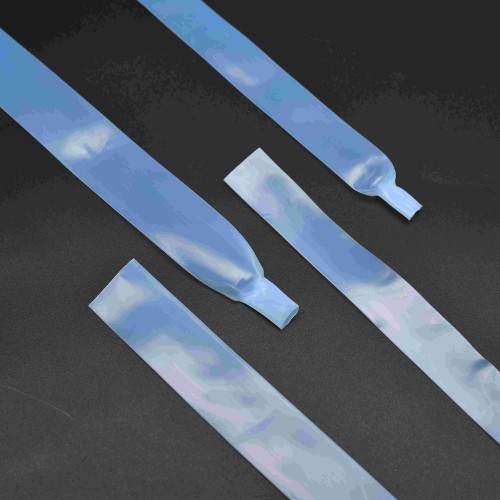

PTFE Heat Shrink Tubing is made from high-performance polytetrafluoroethylene (PTFE) and is a premium heat-shrinkable protective material that combines excellent temperature resistance, chemical stability, and electrical insulation properties. When heated, it shrinks rapidly and tightly wraps around the protected object, forming a durable protective layer that effectively resists high temperatures, corrosion, moisture, and mechanical wear in harsh environments. Available in 1.7:1, 2:1, and 4:1 shrink ratios, this product meets the needs of various applications and is widely used in the electronics, electrical, chemical, medical, and aerospace industries.

PTFE Heat Shrink Tubing is made from high-performance polytetrafluoroethylene (PTFE) and is a premium heat-shrinkable protective material that combines excellent temperature resistance, chemical stability, and electrical insulation properties. When heated, it shrinks rapidly and tightly wraps around the protected object, forming a durable protective layer that effectively resists high temperatures, corrosion, moisture, and mechanical wear in harsh environments. Available in 1.7:1, 2:1, and 4:1 shrink ratios, this product meets the needs of various applications and is widely used in the electronics, electrical, chemical, medical, and aerospace industries.

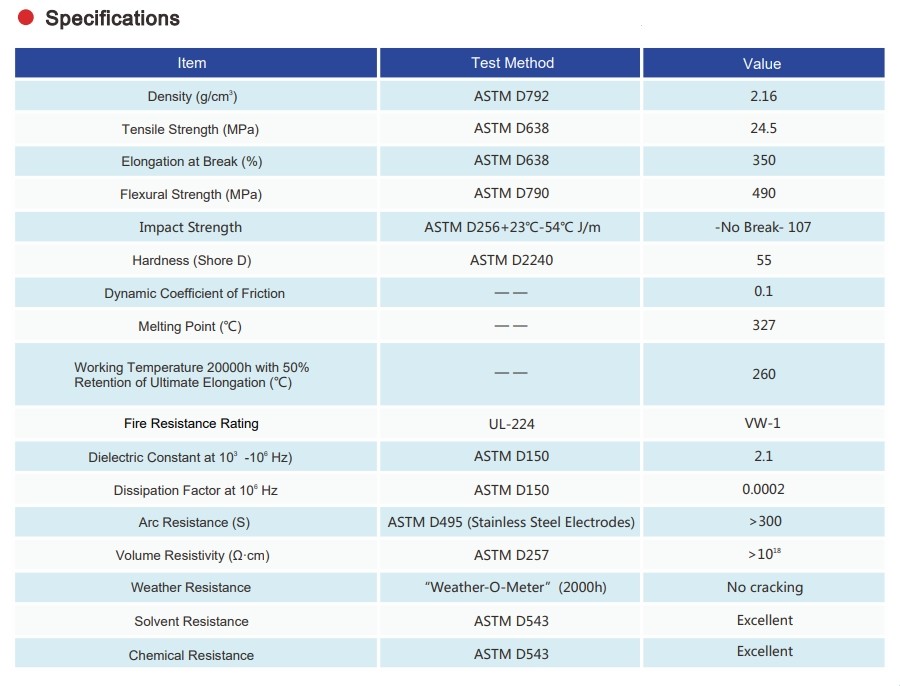

PTFE Heat Shrink Tubing can operate continuously in high-temperature environments, with a sustained operating temperature up to 260°C (500°F), and it can even withstand higher temperatures for short periods. This ensures that in high-thermal-load applications such as motors, transformers, and high-temperature pipelines, the tubing maintains dimensional stability and performance without softening, cracking, or carbonizing even after prolonged exposure.

PTFE is renowned for its near-total chemical inertness, making it resistant to strong acids, alkalis, solvents, oils, salt mist, and corrosive gases. This makes PTFE Heat Shrink Tubing particularly suitable for highly corrosive environments such as chemical pipelines, laboratories, and marine applications, ensuring that internal cables and components remain protected and achieve extended service life.

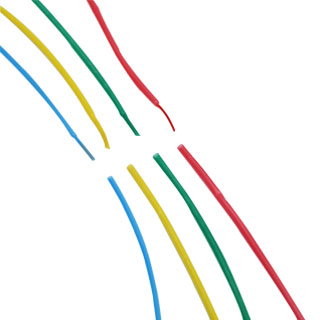

With a low dielectric constant and high breakdown voltage, PTFE provides outstanding electrical insulation, effectively preventing current leakage and short circuits. PTFE Heat Shrink Tubing delivers stable insulation protection even in high-frequency or high-voltage electrical systems, making it ideal for use in electronic components, sensors, wire harnesses, and high-frequency cables — improving overall safety and reliability.

PTFE features an exceptionally low coefficient of friction, with a smooth surface that resists dust and contaminant adhesion. PTFE Heat Shrink Tubing minimizes friction between wires and surrounding components, preventing wear, abrasion, and energy loss — making it particularly suitable for applications with frequent motion or mechanical contact.

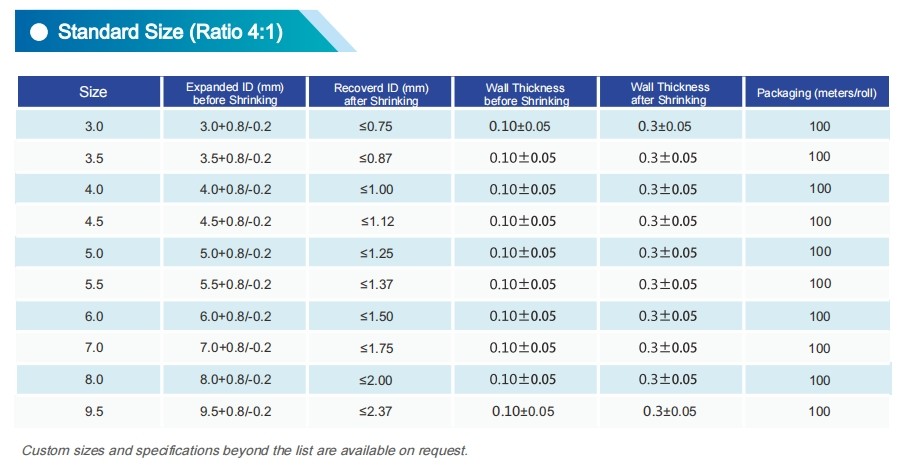

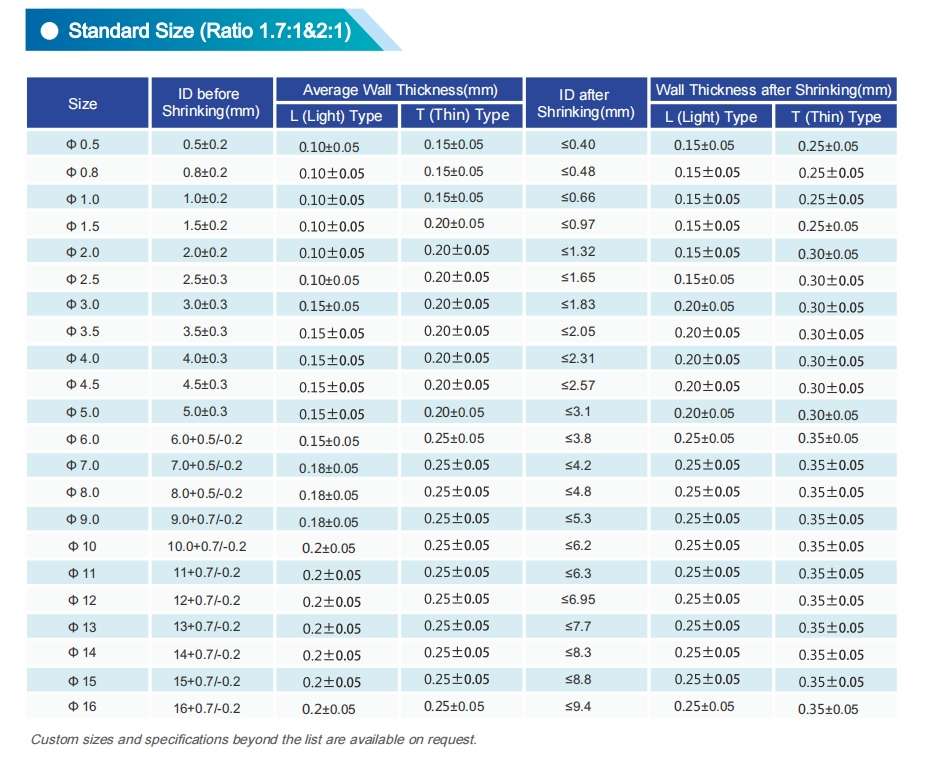

Available in 1.7:1, 2:1, and 4:1 shrink ratios, this tubing can accommodate a wide range of object sizes and shapes. Even for irregular connectors, bends, or complex-shaped devices, PTFE Heat Shrink Tubing shrinks evenly and tightly, ensuring consistent protection across the entire surface.

This product complies with RoHS, REACH, and FDA regulations and has passed UL/C-UL VW-1 flame-retardant certification, offering excellent flame resistance. These certifications ensure that PTFE Heat Shrink Tubing meets global environmental and safety requirements, making it suitable for export and high-standard industrial applications.

Product Advantages

Product Advantages1) Reliable Protection

PTFE heat shrink tubing offers outstanding defense against chemicals, high temperatures, moisture, and particle ingress, ensuring long-term cable and component safety. Thanks to PTFE’s chemically inert molecular structure, it resists acids, bases, and solvents, preventing corrosion or material degradation. After heat shrinking, it forms a dense, moisture-repellent encapsulation that blocks liquid and gas penetration, while its low surface energy minimizes contaminant adhesion and salt spray damage. This robust protection significantly reduces field failures, extends service life, and lowers maintenance costs — a major advantage in chemical processing, marine, and other harsh industrial environments.

2) Easy Installation & Reliable Conformability

Engineered for efficiency, PTFE heat shrink tubing delivers consistent shrink ratios (1.7:1, 2:1, 4:1) for precise and predictable results. Its natural flexibility allows it to conform to irregular connectors, bends, and multi-wire bundles without gaps or wrinkling, and its non-stick surface keeps assembly areas clean. This combination simplifies installation, shortens assembly time, and reduces labor costs. For automated production lines, it ensures a neat, professional finish and enhances production yield.

3) Long-Term Durability & Stability

Built to withstand demanding environments, PTFE heat shrink tubing maintains its mechanical strength, electrical insulation, and dimensional stability over time. Its strong carbon–fluorine bonds give it exceptional thermal stability, allowing continuous operation up to 260 °C without creeping or degrading. It is also resistant to UV light and oxidation, preventing surface cracking or chalking even during prolonged outdoor use. This long-lasting performance improves Mean Time Between Failures (MTBF) and reduces replacement frequency, making it ideal for aerospace, energy, and medical applications where reliability is critical.

4) Versatility & Regulatory Compliance

With its combination of heat resistance, chemical resistance, insulation, and low friction, PTFE heat shrink tubing can address multiple application needs across electronics, aerospace, medical, and industrial sectors. Manufactured under strict process control, it meets RoHS, REACH, and FDA requirements and holds UL/C-UL VW-1 flame resistance certification. These verified safety and compliance standards simplify global market entry, reduce testing costs, and help customers achieve faster certification of their finished products.

Application Fields

Application FieldsPTFE heat shrink tubing finds wide-ranging applications in various fields, including but not limited to:

Electronics and Electrical Industry: Used for wire and cable insulation, connector protection, and more.

Medical Devices: Applied for insulation and protection of medical equipment.

Chemical Industry: Employed to protect pipelines, valves, and instrumentation from chemical corrosion.

Aerospace Sector: Used for insulation and protection in aerospace electronics and equipment.

FAQ:

PTFE Heat Shrink Tubing is made of materials such as PTFE and polyolefin, which have good elasticity and plasticity. When heated by a heat source, the internal materials will flow and uniformly adhere to the protected object. As the temperature increases, the PTFE heat shrink tubing will shrink and tightly wrap around the protected object, playing a protective and sealing role.

When using PTFE Heat Shrink Tubing, first place the protected object inside the tubing, and then use a heat source (such as a hot air gun or oven) to heat the PTFE heat shrink tubing, causing it to shrink and tightly wrap around the protected object. During the heating process, it is necessary to pay attention to controlling the temperature and time to avoid excessive heating causing damage or foaming of the pipes.

Yes, PTFE Heat Shrink Tubing has good high-temperature resistance and can be used in high-temperature environments. Its maximum operating temperature can reach 260 ℃ and it can maintain stable performance even in long-term high-temperature environments.

Compared with other types of pipes, PTFE Heat Shrink Tubing pipes have better heat resistance, electrical insulation, chemical stability, aging resistance and other advantages, and are more convenient to operate. In addition, its contraction ratio is large and fast, which can better adapt to various shapes of protected objects.