Heat-shrinkable Silicone Rubber Tubing has become a staple in various industries due to its exceptional properties, such as high-temperature resistance, durability, and flexibility. From electrical applications to medical devices, its versatility has made it a sought-after material, especially for wholesale buyers looking for cost-effective solutions.

What is Heat-shrinkable Silicone Rubber Tubing?

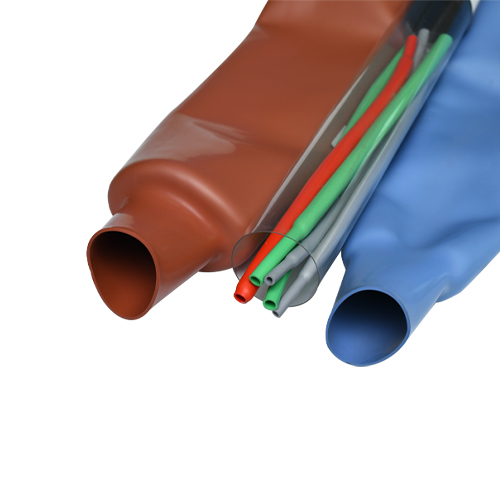

Heat-shrinkable silicone rubber tubing is designed to shrink when exposed to heat, providing a tight, protective layer around cables, wires, or other components. Unlike traditional rubber tubing, which maintains its original size, heat-shrinkable tubing contracts to conform to the shape of the object it covers. This unique feature is particularly beneficial for insulation, sealing, and protection in demanding environments.

For example, Alpha Wire’s heat-shrinkable silicone tubing is widely used in both automotive and electronic applications. It shrinks to half of its original diameter, offering excellent electrical insulation and protection from moisture, dust, and chemicals.

Advantages of Wholesale Heat-Shrinkable Silicone Rubber Tubing

One of the most appealing aspects of purchasing heat-shrinkable silicone rubber tubing wholesale is the cost savings it provides for businesses that require large quantities. Bulk orders can significantly reduce the price per unit, making it a budget-friendly option for manufacturers. Additionally, these tubes offer remarkable flexibility and resistance to high temperatures, making them suitable for various applications, from medical devices to automotive wiring.

TE Connectivity’s heat-shrinkable silicone tubing, for instance, is favored in the military and aerospace sectors, where protection against extreme temperatures and rugged environments is crucial. This tubing can withstand temperatures from -55°C to +200°C, making it ideal for high-performance applications.

Key Applications of Heat-Shrinkable Silicone Rubber Tubing

Heat-shrinkable silicone rubber tubing is widely used in several industries. In the electrical sector, it serves as an excellent insulation material for wires and cables, providing protection against short circuits and environmental hazards. In medical applications, it is used in catheters, feeding tubes, and other devices that require both flexibility and sterilization resistance.

For instance, Advanced Polymers manufactures silicone tubing used in medical catheters, providing the required durability and high-temperature resistance. This type of tubing is essential in medical procedures that demand sterile and reliable materials.

Why Choose Wholesale Heat-Shrinkable Silicone Rubber Tubing?

Wholesale purchases of heat-shrinkable silicone tubing are particularly advantageous for businesses. Not only do they benefit from lower per-unit costs, but they also gain access to a consistent and reliable supply of materials. Companies like Amphenol offer bulk orders to the automotive industry, allowing manufacturers to maintain a steady supply of tubing while keeping costs down.

Furthermore, wholesalers typically offer a variety of sizes and customizations, which can be crucial for businesses with specific needs. Customization can range from the thickness of the tubing to the colors and shrink ratios, providing businesses with a tailored solution for their products.

Quality Considerations When Buying Wholesale

When purchasing heat-shrinkable silicone rubber tubing, it is essential to consider the quality of the product. Factors such as the shrink ratio, wall thickness, and temperature tolerance must meet the required specifications for the intended application. For example, UL-certified silicone tubing is often used in high-performance electrical systems, like those found in Tesla’s electric vehicles, where safety and durability are paramount.

Choosing a reliable supplier that adheres to international quality standards, such as RoHS compliance or UL certification, is critical to ensuring the product meets industry-specific regulations and performs as expected.

Challenges in the Market

Despite the many advantages, the market for heat-shrinkable silicone rubber tubing does face challenges. One of the most notable issues is the fluctuation in the price of raw silicone materials. In recent years, the price of silicone has risen due to supply chain disruptions, particularly in regions like China, where most of the raw material is produced. This increase in raw material costs can affect wholesale prices and, in turn, the pricing structure for end consumers.

Additionally, businesses must be cautious when selecting suppliers, as the quality of heat-shrinkable silicone tubing can vary significantly. Ensuring consistency in product quality is essential to avoid the risk of defective products and delays in the production process.

Sustainability Considerations

Another growing concern in the industry is sustainability. As consumers and businesses alike become more environmentally conscious, manufacturers of heat-shrinkable silicone rubber tubing are moving towards more sustainable practices. Companies like Dow Corning are now offering eco-friendly alternatives made from biodegradable materials, helping to reduce the environmental impact of production and disposal.

Sustainable manufacturing processes, such as minimizing waste and recycling materials, are becoming standard practices in the silicone tubing industry. Businesses opting for these sustainable options can not only improve their environmental footprint but also appeal to a growing market of eco-conscious consumers.

The Future of Heat-Shrinkable Silicone Rubber Tubing

The future of heat-shrinkable silicone rubber tubing looks promising, particularly with the rise of electric vehicles (EVs) and renewable energy sectors. As electric vehicles require efficient, high-performance components that can withstand heat and electrical interference, the demand for heat-shrinkable silicone tubing is expected to rise. Similarly, the increasing adoption of solar energy and smart grid technologies, which rely on high-quality insulation, will further drive demand.

According to a report by Global Market Insights, the global heat-shrinkable silicone tubing market is expected to grow at a compound annual growth rate (CAGR) of 8% through 2027, fueled by the expanding need for insulation materials in industries like automotive, electrical, and renewable energy.

Conclusion

Heat-shrinkable silicone rubber tubing is an indispensable material in industries ranging from automotive to medical, offering protection, insulation, and durability in demanding applications. Wholesale purchases provide businesses with cost-effective solutions while ensuring a steady supply of high-quality materials. As the market grows and sustainability becomes more important, manufacturers are adapting to meet new demands. Whether you are purchasing for a large-scale production or looking for customization options, heat-shrinkable silicone rubber tubing continues to play a crucial role in today’s technology-driven world.