PVC conduit has long been regarded as a cost-effective alternative to metal conduit systems. However, in recent years, contractors, engineers, electricians, and buyers have increasingly asked a common question: why is PVC conduit so expensive? What was once considered an economical choice now appears to carry a noticeably higher price tag, especially when compared to previous years.

To understand the real reasons behind rising PVC conduit costs, it is essential to examine raw materials, manufacturing processes, logistics, performance requirements, and market demand. This article provides a comprehensive explanation while also addressing related topics such as can PVC pipe bend, PVC tube types, PVC pipe fittings, clear PVC pipe, thin PVC pipe conduit, PVC shipping tubes, and overall PVC market dynamics.

Understanding What PVC Conduit Is

PVC conduit is a protective tubing system used to route and safeguard electrical wiring. Made from polyvinyl chloride (PVC), it is lightweight, corrosion-resistant, non-conductive, and suitable for both indoor and outdoor use. Compared with metal conduit, PVC conduit offers easier installation, chemical resistance, and long service life.

However, not all PVC conduit is the same. Variations in wall thickness, diameter, flexibility, and certifications significantly affect price.

The Primary Reasons PVC Conduit Has Become More Expensive

1. Rising Cost of PVC Raw Materials

At the core of every PVC tube is resin derived from petroleum and chlorine. Over the past few years, petroleum price volatility has directly impacted the cost of PVC resin. When oil prices increase, so does the cost of producing PVC.

In addition, environmental regulations have increased compliance costs for chemical manufacturers. Cleaner production processes, emissions controls, and waste treatment all add expenses that are ultimately passed down the supply chain.

This affects not only conduit but also PVC pipe fittings, clear PVC pipe, thin PVC pipe, and even PVC shipping tubes used in packaging and logistics.

2. Supply Chain Disruptions and Logistics Costs

Another major reason why PVC conduit is so expensive lies in transportation and logistics. PVC products are bulky but relatively lightweight, making shipping costs disproportionately high.

Fuel price increases raise freight costs

Container shortages impact global PVC supply

Longer lead times increase inventory holding costs

Even domestic PVC conduit production relies on globally sourced raw materials. As shipping expenses rise, the final cost of PVC conduit inevitably follows.

3. Increased Demand Across Multiple Industries

PVC is no longer limited to plumbing and electrical applications. Today, PVC is widely used in:

Construction and infrastructure

Agriculture and irrigation

Medical tubing

Industrial fluid handling

Packaging (including PVC shipping tubes)

With demand rising across industries, manufacturers prioritize high-margin or high-volume products, tightening availability and driving prices higher.

For example, clear PVC pipe and flexible PVC tube are increasingly used in industrial visualization and food-grade systems, competing for the same resin supply as electrical conduit.

Performance Standards Drive Higher Manufacturing Costs

4. Stricter Electrical and Building Codes

Modern PVC conduit must meet rigorous safety and performance standards, including:

Flame retardancy

UV resistance

Impact resistance

Temperature tolerance

Crush strength

Achieving these properties requires precise formulations, additives, and quality control processes. Compared to standard thin PVC pipe, electrical conduit is often thicker, stronger, and engineered for long-term durability.

This is one key reason why PVC conduit costs more than general-purpose PVC pipe.

5. Wall Thickness and Structural Requirements

Not all PVC pipes are designed to protect electrical wiring. Thin PVC pipe may be suitable for drainage or low-pressure applications, but conduit must withstand mechanical stress and environmental exposure.

Heavier wall thickness means:

More raw material per meter

Longer cooling cycles during extrusion

Higher energy consumption

These factors increase manufacturing cost per unit.

Can PVC Pipe Bend? Flexibility vs. Cost

A common question in conduit installation is: can PVC pipe bend?

Heat Bending PVC Conduit

Yes, PVC conduit can be bent using controlled heat. However, conduit designed for bending must maintain structural integrity after deformation. This requires:

Specialized PVC formulations

Uniform wall thickness

Controlled extrusion tolerances

These features raise production costs compared to standard rigid PVC tube products.

Flexible PVC Tube vs. Rigid Conduit

While flexible PVC tubing exists, it is typically used for fluid transfer, not electrical protection. Flexible PVC contains plasticizers, which:

Reduce long-term rigidity

Lower impact resistance

Limit suitability for electrical codes

Therefore, rigid PVC conduit remains the standard, despite being more expensive to produce.

The Role of PVC Pipe Fittings in Overall System Cost

A conduit system is incomplete without PVC pipe fittings, such as elbows, couplings, adapters, and junction boxes.

Why PVC Pipe Fittings Are Also Expensive

Precision molds are costly

Tight tolerances are required

Code compliance testing increases expense

Multiple sizes and standards increase inventory complexity

High-quality PVC pipe fittings must match conduit strength and durability, contributing to the overall perception that PVC conduit systems are expensive.

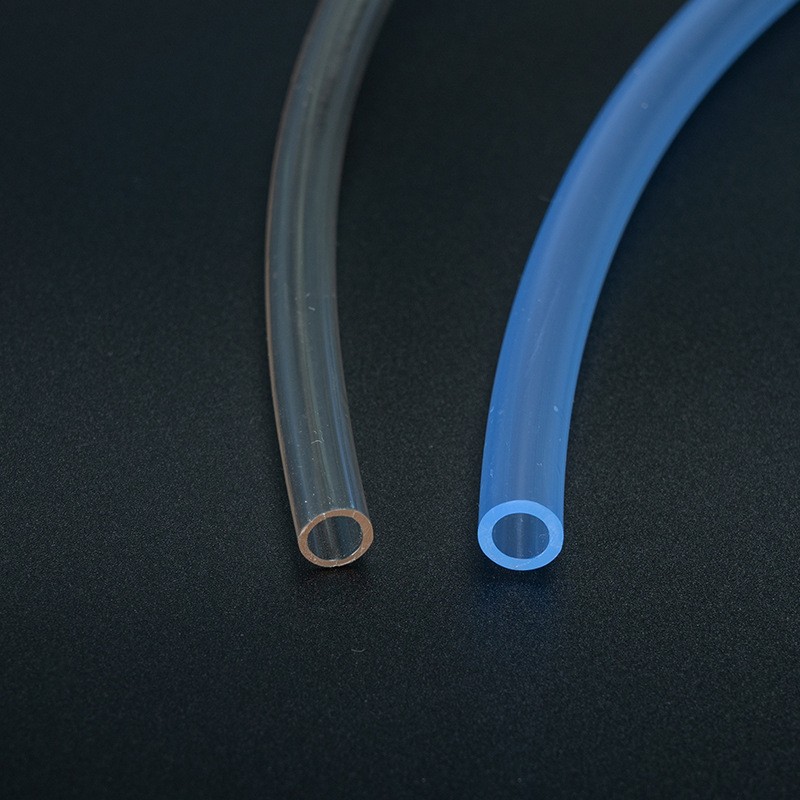

Clear PVC Pipe and Specialty PVC Products

Clear PVC Pipe Costs More Than Standard PVC

Clear PVC pipe is often used where visual inspection of flow is necessary. Achieving transparency requires:

Higher purity PVC resin

Tighter extrusion controls

Lower defect tolerance

These factors make clear PVC significantly more expensive than opaque conduit, even though they share similar base materials.

Thin PVC Pipe vs. Conduit: Why the Price Gap Exists

It’s tempting to compare conduit pricing to thin PVC pipe, but the applications and requirements are fundamentally different.

| Feature | Thin PVC Pipe | PVC Conduit |

|---|---|---|

| Wall thickness | Minimal | Heavy-duty |

| Electrical rating | None | Code compliant |

| UV resistance | Limited | Required |

| Impact resistance | Low | High |

| Price | Lower | Higher |

PVC conduit is engineered for protection and safety, not just material transport.

PVC Shipping Tubes: Another Cost Indicator

PVC shipping tubes are used for posters, documents, and industrial components. Although they are not electrical conduit, their rising prices reflect the same market pressures:

Resin cost increases

Shipping expenses

Manufacturing energy costs

This further demonstrates that the issue is not conduit alone, but the broader PVC market.

Is PVC Conduit Still Worth the Price?

Despite higher costs, PVC conduit continues to offer strong value:

Corrosion resistance (ideal for underground use)

Long service life

Low maintenance

Easy installation compared to metal

In many environments, PVC conduit outperforms alternatives over time, offsetting its initial cost.

How Buyers Can Reduce PVC Conduit Costs

While you may not control global PVC prices, you can optimize purchasing decisions:

Buy in bulk to reduce per-unit shipping costs

Source directly from manufacturers instead of distributors

Match conduit grade to application (don’t over-specify)

Use standardized PVC pipe fittings to reduce custom tooling costs

Understanding whether a project truly requires heavy conduit or if a thinner solution is acceptable can lead to meaningful savings.

Conclusion

So, why is PVC conduit so expensive? The answer lies in a combination of rising raw material prices, stricter regulations, increased global demand, higher logistics costs, and enhanced performance requirements. Compared to standard PVC tube, thin PVC pipe, or even PVC shipping tubes, conduit is a highly engineered product designed for safety, durability, and long-term performance.

When evaluated in terms of lifecycle cost, reliability, and compliance, PVC conduit remains a competitive and often superior choice—despite its higher upfront price. Understanding these factors allows engineers, contractors, and buyers to make more informed, cost-effective decisions in today’s evolving PVC market.