The GD-SCS Self-Closing Sleeving is crafted from polyester monofilament and multifilament, providing properties such as fire resistance, abrasion resistance, flexibility, dustproof quality, and ease of use. Its open design is conducive to the retrofitting, reinstallation, maintenance, and inspection of internal wire harnesses. This product is extensively utilized in various industries including telecommunications, high-speed rail, automotive, automation equipment, and for instrument and meter circuits, as well as cables, wire harnesses, and tubing. It is particularly well-suited for applications involving wire harnesses with irregular shapes.

Self-Closing Sleeving simplifies cable management with its flexible, durable design. It effortlessly wraps around cable bundles, automatically closing without the need for additional fasteners. This sleeving provides reliable protection against abrasion, heat, and wear, ensuring tidy organization and a professional finish in various applications such as electronics, automotive, and industrial settings.

Quick and Easy Installation: The self-wrapping design allows for fast and straightforward installation without the need for additional fasteners or tools.

Versatility: Self-closing sleeving is versatile and can be used in a wide range of applications, adapting to different cable sizes and shapes.

Flexibility: The material used in self-closing sleeving is typically flexible, providing the ability to conform to the shape of the cables or wires it is protecting.

Protection Against Abrasion: Like other cable sleeving solutions, self-closing sleeving offers effective protection against abrasion, friction, and general wear and tear.

Secure Fit: The self-wrapping feature ensures a secure and snug fit around cables, preventing the sleeving from slipping or becoming loose.

Durable Materials: Often made from durable materials such as nylon or other polymers, ensuring long-term reliability and resistance to environmental factors.

Cable Management: Widely used for organizing and managing cables in electronic devices, computer systems, and various equipment where efficient cable organization is essential.

Automotive Wiring: Applied in the automotive industry to bundle and protect wiring harnesses, offering insulation and safeguarding against abrasion in vehicles.

Industrial Equipment: Used in industrial settings to organize and protect cables in machinery and equipment, preventing damage from harsh working environments.

Home Electronics: Suitable for managing and protecting cables in home electronics and entertainment systems, contributing to a neat and organized appearance.

Office Environments: Applied in office settings to organize and manage cables, contributing to a tidy and efficient workspace.

Telecommunications: Used in the telecommunications industry for bundling and protecting cables in networking and communication systems.

DIY Projects: Popular in do-it-yourself (DIY) projects where cable management and protection are required, offering a user-friendly solution for hobbyists and DIY enthusiasts.

Self-closing sleeving provides a convenient and effective solution for cable organization and protection, offering advantages such as quick installation, adaptability, and reliable cable management across diverse applications.

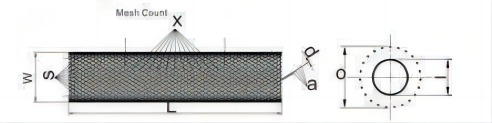

Engineering Picture

FAQ:

Self closing sleeving works through the use of a buckle, clip, or hook-and-loop system that allows the sleeve to secure itself in place. This design ensures a secure fit while also providing easy installation and removal.

Self closing sleeving offers several advantages. It provides a quick and secure method of protecting cords, wires, and hoses from abrasion, impact, and chemical exposure. Additionally, it is lightweight, easy to handle, and does not require any external fasteners or adhesives.

There are various types of self closing sleeving available, including buckle closures, clip closures, and hook-and-loop closures. Each type offers different styles and features based on the specific application requirements.

To use self closing sleeving, simply slide it onto the item or goods being protected. Then, use the built-in mechanism to securely close the sleeve in place. The sleeving can also be cut to length for customized protection

Special packaging, colors, etc., can be customized according to customer requirements.

Product Part | d: Inner Diameter (mm) | Maximum Wrap Diameter (mm) | Packing (Length/Coil) |

SCS-003 | 3 | 4 | 100M |

SCS-005 | 5 | 6 | 100M |

SCS-008 | 8 | 9 | 100M |

SCS-010 | 10 | 11 | 100M |

SCS-013 | 13 | 14 | 100M |

SCS-016 | 16 | 17 | 100M |

SCS-019 | 19 | 20 | 50M |

SCS-025 | 25 | 27 | 25M |

SCS-029 | 29 | 31 | 25M |

SCS-032 | 32 | 34 | 25M |

SCS-038 | 38 | 40 | 25M |

SCS-050 | 50 | 52 | 25M |

Material | Polyester |

Operating Temperature | -50℃-+150℃ |

Melting Point | 240℃±10℃ |

Flame Resistance Rating | 94-V0, DIN 5510, EN45545 |

Certificate | RoHS, REACH |

Standard Colors | Black |

Cutting Tool | Hot Knife Cutter |