The Noise Reduction Self-Closing Sleeving is a premium cable protection solution designed to reduce noise, prevent abrasion, and provide easy installation without disconnecting cables. Featuring a self-wrapping design, it ensures quick application while maintaining strong coverage for electrical wires, harnesses, and tubing systems. Unlike traditional heat shrink tubing for electrical wires, this sleeving offers flexibility and reusability, allowing convenient access for inspection or maintenance.

Ideal for automotive, industrial, home electronics, and audio wiring, this cable protection sleeve delivers exceptional durability, flame resistance, and thermal stability—ensuring long-term reliability even in demanding environments.

Broad Temperature Resistance

Operating Temperature: -50℃ ~ +150℃

Performance Stability: Maintains flexibility without cracking or melting under continuous heat or extreme cold.

High Thermal Melting Point

Melting Point: 240℃ ±10℃

Material Heat Endurance: Prevents deformation or dripping even under accidental high-temperature exposure.

Certified Flame Retardancy

Flame Resistance: UL94-V1 Rated

Fire Protection: Automatically self-extinguishes within 10 seconds without flaming drips, ensuring cable safety.

Environmental Compliance

Certifications: RoHS, Halogen-Free

Toxicity Level: 0% halogen content, safe for automotive and electronic OEM applications.

Noise Reduction Structure

Self-Closing Overlap: 25% wrap overlap structure

Noise Control: Reduces cable friction noise by up to -15 dB in vibration environments (e.g., automotive dashboards).

Abrasion Resistance

Surface Durability: Withstands over 50,000 abrasion cycles (Taber test, H-18 wheel, 1kg load)

Usage Life: Extended durability in environments with constant cable movement.

Strong Tensile Strength

Material Tensile Force: ≥ 120 N (per 25mm width)

Cable Protection: Resistant to stretching and tearing during installation and maintenance.

Professional Cutting Compatibility

Recommended Cutting Tool: Hot Knife Cutter

Edge Integrity: Prevents fraying and ensures sealed, professional-grade finish.

Automotive:

Automotive:Implementation:

Noise Reduction Self-Closing Sleeving is integrated into automotive applications to protect wire harnesses and tubing from abrasion and external factors.

Key Features: Its adaptability and noise reduction properties make it an ideal solution for ensuring a quieter and more reliable automotive electrical system.

Automation Equipment:

Use Case: Commonly employed in automation equipment, the sleeving serves to protect wire harnesses and tubing in robotic and machinery applications.

Significance: It contributes to noise reduction, ensuring a quieter operational environment for automated systems.

Protection in Harsh Environments:

Scenario: Particularly applicable in areas where both protection and abrasion resistance are crucial for wires and hoses.

Benefits: The durable construction of the sleeving enhances the longevity of cables, making it suitable for challenging environments in various industries.

Enhanced Cable Durability:

Context: Noise Reduction Self-Closing Sleeving finds application where wires and hoses require protection from both environmental factors and abrasion.

Result: The sleeving not only minimizes noise but also extends the lifespan of cables, contributing to enhanced overall system reliability.

Integration in Critical Systems:

Application Focus: Especially relevant in critical systems where signal integrity and protection against wear are paramount.

Value: The sleeving ensures that wire harnesses and tubing remain safeguarded, reducing the risk of damage in critical applications.

In summary, the Noise Reduction Self-Closing Sleeving plays a vital role in various industries, including telecommunications, high-speed rail, automotive, and automation equipment. Its adaptability, noise reduction capabilities, and resistance to abrasion make it a valuable solution for ensuring the protection and longevity of wire harnesses and tubing in diverse applications.

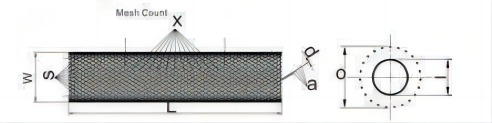

Engineering Picture

FAQ:

What are the features of a Noise Reduction Self-Rolling Textile Sleeve?

A Noise Reduction Self-Rolling Textile Sleeve typically offers good noise reduction properties, high impact resistance, and good insulation properties. The soft material provides a comfortable fit while the self-rolling mechanism ensures a secure fit.

What are the advantages of using a Noise Reduction Self-Rolling Textile Sleeve?

Using a Noise Reduction Self-Rolling Textile Sleeve can provide effective noise reduction and protection for items while also acting as a strain relief solution. The self-rolling feature ensures a snug fit that limits movement and abrasion while the soft material adds extra comfort.

A Noise Reduction Self-Rolling Textile Sleeve can be used for a variety of applications, including protecting delicate items, reducing noise pollution in industrial environments, and providing extra support for items that require extra protection.

A Noise Reduction Self-Rolling Textile Sleeve offers a combination of protective properties and user-friendly features that distinguish it from other types of sleeves. The soft material provides added protection while the self-rolling mechanism ensures a secure fit without the need for external fasteners or adhesives.

Product Part | d: Inner Diameter (mm) | Maximum Wrap Diameter (mm) | Packing (Length/Coil) |

SCK2-005 | 5.0 | 6.0 | 100M |

SCK2-008 | 8.0 | 9.0 | 100M |

SCK2-010 | 10.0 | 11.0 | 100M |

SCK2-013 | 13.0 | 14.0 | 50M |

SCK2-016 | 16.0 | 17.0 | 50M |

SCK2-019 | 19.0 | 20.0 | 25M |

SCK2-025 | 25.0 | 27.0 | 25M |

SCK2-029 | 29.0 | 31.0 | 25M |

SCK2-032 | 32.0 | 34.0 | 25M |

SCK2-038 | 38.0 | 40.0 | 25M |

SCK2-050 | 50.0 | 52.0 | 25M |

Material | Polyester Monofilament + Polyester Multifilament |

Operating Temperature | -50℃-+150℃ |

Melting Point | 240℃±10℃ |

Flame Resistance Rating | UL94-V1 |

Certificate | RoHS, Halogen-Free |

Standard Colors | Black |

Cutting Tool | Hot Knife Cutter |