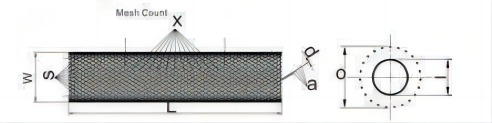

The Wave Split Self-Closing Sleeving is a high-performance cable protection sleeve designed to provide superior flexibility, abrasion resistance, and thermal stability for wire and cable harness systems. Featuring an innovative wave split self-closing structure, this self closing sleeving allows for easy installation without disconnecting cables or connectors. Its open, self-wrapping design ensures quick maintenance and reliable protection for both individual wires and bundled cables.

Made from durable PET monofilament, this sleeving delivers exceptional mechanical strength while remaining lightweight and easy to handle. Whether used in automotive, electrical, or industrial applications, the Wave Split Self-Closing Sleeving offers dependable performance in demanding environments.

Wide Temperature Range (-50℃ to +150℃)

The wave split self-closing sleeving maintains flexibility and dimensional stability across extreme temperatures, from cold outdoor installations to high-heat industrial zones. This ensures reliable protection for wiring in vehicles, machinery, and electronic systems.

High Melting Point (240℃ ±10℃)

Constructed from high-quality PET material, the cable protection sleeve resists deformation and melting even under continuous thermal exposure. This property makes it ideal for use near engines, motors, and heating elements.

Flame Retardant Performance (UL94 V2)

The self closing sleeving meets UL94 V2 flame resistance standards, effectively preventing fire spread and ensuring electrical safety. It offers enhanced protection for critical wiring systems in high-risk environments.

Certified Safe and Environmentally Friendly (RoHS, Halogen-Free)

The cable protection sleeve complies with international safety and environmental certifications — RoHS and Halogen-Free — ensuring it contains no harmful substances and is safe for electrical and electronic applications.

Innovative Wave Split Design for Easy Installation

The unique wave-split opening allows users to wrap or remove the self closing sleeving easily, even on pre-installed cables. The structure tightly encloses cables without the need for adhesives or additional fastening tools.

Superior Abrasion and Chemical Resistance

The woven PET construction offers exceptional durability against mechanical wear, oils, and chemicals. It prevents cable damage caused by friction, bending, or vibration, extending the service life of wire harness systems.

Professional Appearance and Noise Reduction

The wave split cable protection sleeve not only protects but also organizes wiring neatly, reducing clutter and vibration noise — perfect for professional automotive and industrial installations.

Standard Color and Cutting Method

Available in Black, this sleeving provides a clean, uniform appearance suitable for any environment. For precise, fray-free cuts, a hot knife cutter is recommended, ensuring smooth edges and durability after cutting.

Quick installation and removal without disconnecting cables.

High-temperature and flame-retardant performance for enhanced safety.

Certified eco-friendly materials (RoHS, Halogen-Free) for responsible manufacturing.

Durable PET structure ensures long-term abrasion protection.

Self-wrapping, flexible, and reusable cable protection sleeve design.

Clean black color for professional wire harness management.

Applications

The Wave Split Self-Closing Sleeving is suitable for a wide range of industries and environments:

Automotive: Wire harness protection in engines and under-dashboard areas.

Electrical and Electronics: Power, communication, and data cable management.

Industrial Machinery: Cable protection against vibration and heat.

Aerospace and Marine: Lightweight protection for dynamic wiring systems.

Home and Office: Organizing and protecting audio, computer, and power cables.

Precautions

Use a hot knife cutter to achieve smooth and sealed sleeve edges.

Avoid stretching the sleeving beyond its designed flexibility range.

Do not expose to direct flame or continuous heat above +150℃.

Store in a dry, shaded environment to maintain material integrity.

Clean cables before application to ensure a secure wrap.

FAQ

Q1: What makes the Wave Split Self-Closing Sleeving different from other types?

A1: The wave split design allows easier installation while providing enhanced flexibility and durability compared to traditional flat-split sleeves.

Q2: Can the cable protection sleeve be reused?

A2: Yes, the self closing sleeving is reusable and can be opened or removed without cutting, making it ideal for maintenance and upgrades.

Q3: Is it flame resistant?

A3: Yes, it meets UL94 V2 flame resistance standards, providing reliable protection against ignition and fire spread.

Q4: What tools are recommended for cutting?

A4: A hot knife cutter is recommended to achieve clean cuts and prevent fraying.

Q5: Is it safe for electrical applications?

A5: Absolutely. It is RoHS and Halogen-Free certified, ensuring it’s safe for electrical, automotive, and industrial use.

Product Part | d: Inner Diameter (mm) | Maximum Wrap Diameter (mm) | Packing (Length/Coil) |

SCK1-005 | 5 | 6 | 100M |

SCK1-008 | 8 | 9 | 100M |

SCK1-010 | 10 | 11 | 100M |

SCK1-013 | 13 | 14 | 50M |

SCK1-016 | 16 | 17 | 50M |

SCK1-019 | 19 | 20 | 25M |

SCK1-025 | 25 | 27 | 25M |

SCK1-029 | 29 | 31 | 25M |

SCK1-032 | 32 | 34 | 25M |

SCK1-038 | 38 | 40 | 25M |

SCK1-050 | 50 | 52 | 25M |

Material | Polyester |

Operating Temperature | -50℃-+150℃ |

Melting Point | 240℃±10℃ |

Flame Resistance Rating | UL94 V2 |

Certificate | RoHS, Halogen-Free |

Standard Colors | Black |

Cutting Tool | Hot Knife Cutter |